Don't hesitate to send a message

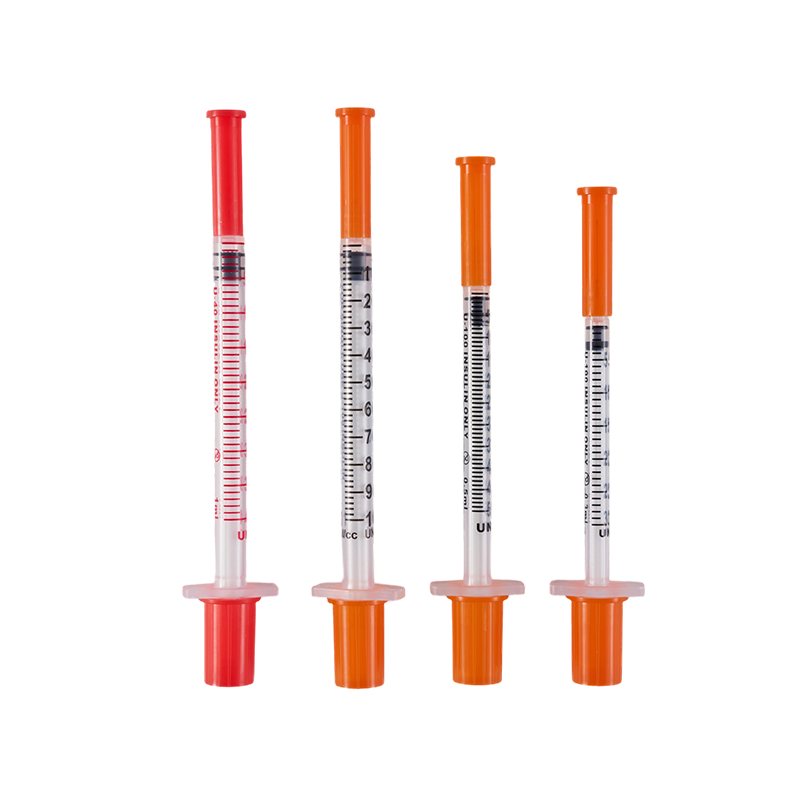

The design and production comply with ISO8537. The plastic parts are moulded by ...

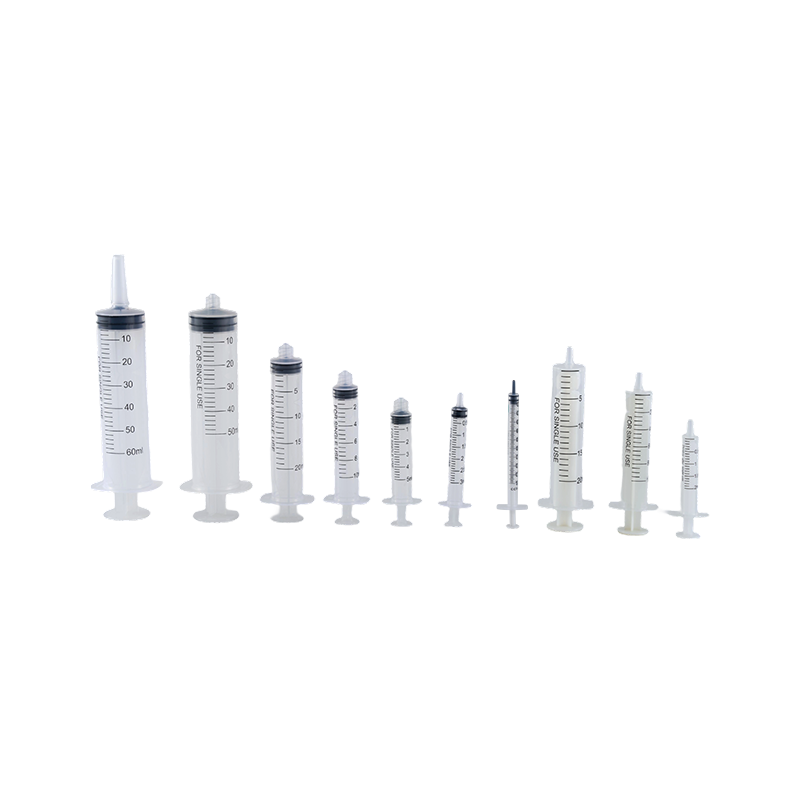

Over the years, innovations have led to various designs, with the Disposable Injection Syringe, Disposable Hypodermic Syringe, and Disposable Syringe With Needle being the most commonly used in clinical and laboratory settings. While all serve similar purposes, their designs, applications, and construction differ significantly, influencing both safety and efficiency in medical environments.

The development of the Disposable Injection Syringe revolutionized the medical field by addressing one of the most critical issues—cross-contamination. Before disposable models became standard, reusable syringes required manual sterilization, which increased risks and consumed valuable time. The introduction of the Disposable Hypodermic Syringe provided healthcare workers with a sterile, single-use option that improved infection control and simplified clinical workflow.

Today, most facilities prefer using the Disposable Syringe With Needle, as it combines convenience with precision. Its integrated design allows for faster preparation, reducing the number of steps needed during injections or fluid administration. This innovation not only enhances efficiency but also minimizes the potential for handling errors.

While the Disposable Injection Syringe, Disposable Hypodermic Syringe, and Disposable Syringe With Needle share a basic function—delivering or extracting fluids—their structures reflect different purposes.

Each design reflects specific requirements of the healthcare environment, and medical staff choose according to the type of medication, injection site, and procedural needs.

In modern production, the Disposable Injection Syringe and Disposable Hypodermic Syringe are typically made from medical-grade polypropylene and polyethylene, materials known for strength, clarity, and chemical resistance. The Disposable Syringe With Needle may include stainless steel needles coated for smooth insertion and durability.

Manufacturing precision is essential because even minor variations in barrel diameter, plunger fit, or needle angle can affect performance. Advanced molding techniques and automated assembly systems ensure that each Disposable Injection Syringe meets strict international standards for safety and consistency. Similarly, every Disposable Hypodermic Syringe undergoes quality checks to guarantee sterility and function. For facilities that handle large volumes, bulk packaging of the Disposable Syringe With Needle supports efficient supply chain management while maintaining hygiene.

All three syringe types—Disposable Injection Syringe, Disposable Hypodermic Syringe, and Disposable Syringe With Needle—are sterilized using methods such as ethylene oxide gas or gamma radiation before packaging. Maintaining sterility is crucial to prevent contamination before medical use.

However, the growing global focus on environmental responsibility is influencing syringe manufacturing practices. Many companies are exploring eco-friendly packaging, recyclable plastics, and energy-efficient production methods for Disposable Injection Syringe lines. Similarly, Disposable Hypodermic Syringe manufacturers are testing biodegradable polymers to reduce medical waste impact. The Disposable Syringe With Needle is also being redesigned with lighter components to plastic use while retaining durability and sterility.

Selecting the appropriate syringe depends on various factors—such as the medication type, injection depth, and patient sensitivity. A Disposable Injection Syringe is ideal for routine injections and fluid administration. The Disposable Hypodermic Syringe suits more delicate applications, including precise intramuscular or subcutaneous injections. For convenience and integrated safety, the Disposable Syringe With Needle provides a one-piece solution that streamlines medical procedures.

Healthcare providers benefit from understanding these design distinctions. Using the correct syringe enhances patient safety, ensures accurate dosage, and improves workflow efficiency in hospitals, clinics, and laboratories.

The design and production comply with ISO8537. The plastic parts are moulded by ...

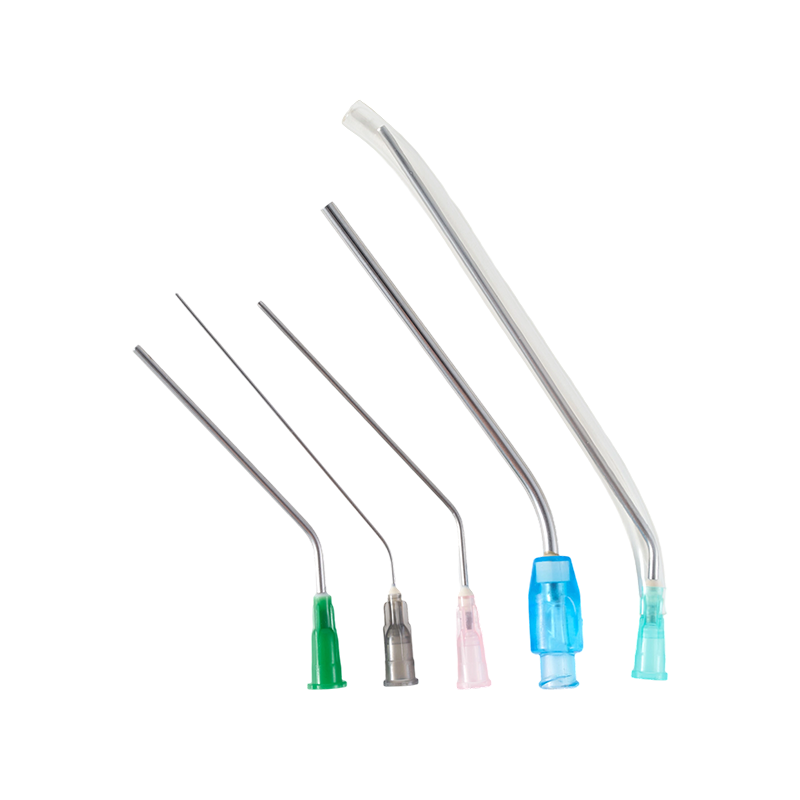

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

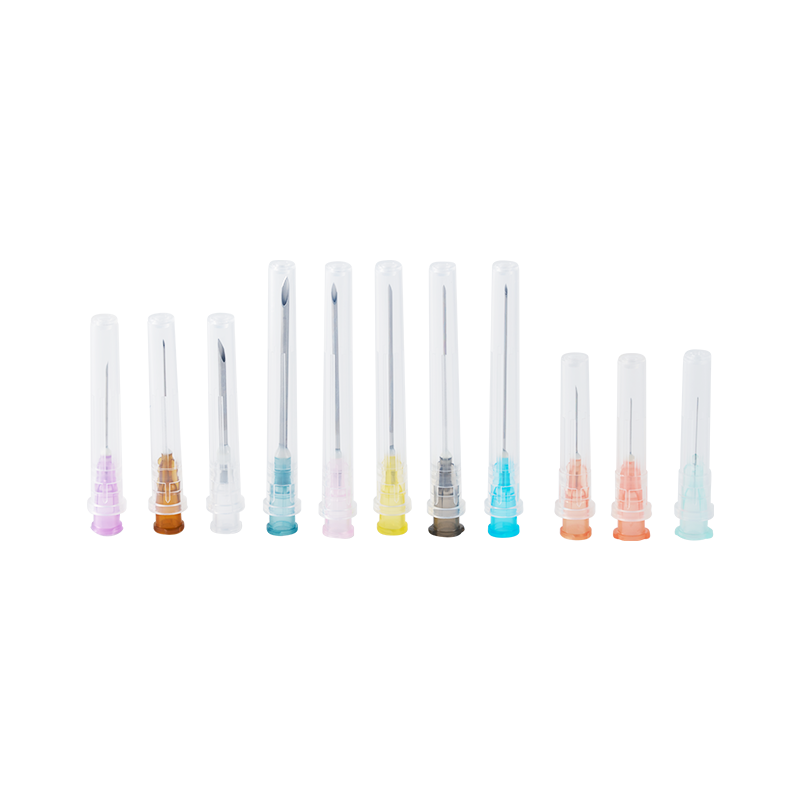

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...