Don't hesitate to send a message

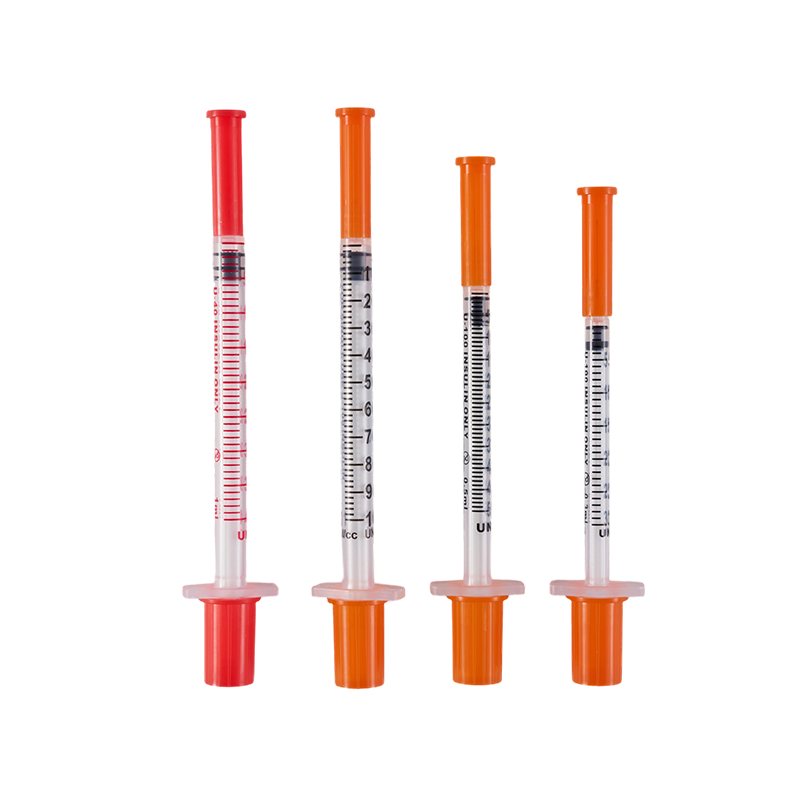

The design and production comply with ISO8537. The plastic parts are moulded by ...

A Syringe And Needle Producer plays a quiet but vital role in healthcare. Behind every injection, vaccination, or blood draw lies a combination of precision design, clean materials, and strict production standards. While many people never think about who makes syringes and needles, the story behind their creation is worth knowing-especially for hospitals, distributors, and laboratories that rely on consistent, sterile tools every day.

So, what really happens inside a professional syringe and needle production facility, and what should you look for in a trustworthy producer?

Every reliable Syringe And Needle Producer begins with the right raw materials. Medical-grade polypropylene is often the go-to choice for syringes because it's durable, transparent, and chemically stable. The material does not react with medication and stays intact under sterilization.

The needles, on the other hand, are made using high-quality stainless steel. The bevel of each needle tip is laser polished to create a smooth, clean puncture-minimizing discomfort and tissue damage. This level of refinement is only possible when a producer uses precision molding and finishing equipment, supported by a controlled cleanroom environment.

In the medical field, “clean” isn't just a visual impression-it's a measurable standard. A trusted Syringe And Needle Producer operates under ISO-certified production systems. The manufacturing lines are tightly controlled for temperature, air purity, and humidity to prevent contamination at every stage.

Sterilization is another critical step. Ethylene oxide gas sterilization is commonly used because it can kill microorganisms without damaging the syringe or needle material. After sterilization, each syringe and needle is sealed in triple-layer packaging to maintain sterility during transportation and storage.

This detailed process protects users from cross-infection risks and gives medical professionals the confidence that every piece they handle is ready for use.

When you hold a syringe, the small details matter. A well-made syringe should have a clear, accurate scale that allows for precise dosage measurement-from as small as 0.1ml up to 60ml. These markings are not just printed-they're moulded into the body of the syringe through great injection technology, making them long-lasting and resistant to fading.

A professional Syringe And Needle Producer also considers ergonomic design. The plunger should move smoothly without excessive resistance, and the protective cap should fit securely. Some producers even design syringes with safety features that prevent accidental needle sticks, protecting healthcare workers as well as patients.

Disposable syringes and needles may seem simple, but they serve countless roles-from clinical injections and vaccinations to laboratory sampling and biopharmaceutical filling. A Syringe And Needle Producer must understand these diverse needs to offer flexible specifications and packaging options.

This versatility is not only about meeting client requirements-it's about supporting the reliability of the entire medical supply chain. When syringes and needles function consistently, medical processes flow smoothly, patients receive accurate treatment, and hospitals can maintain trust in their daily operations.

A Syringe And Needle Producer is more than just a manufacturer-it's a silent guardian of healthcare quality. Every small component reflects a deep understanding of safety, precision, and practicality.

The design and production comply with ISO8537. The plastic parts are moulded by ...

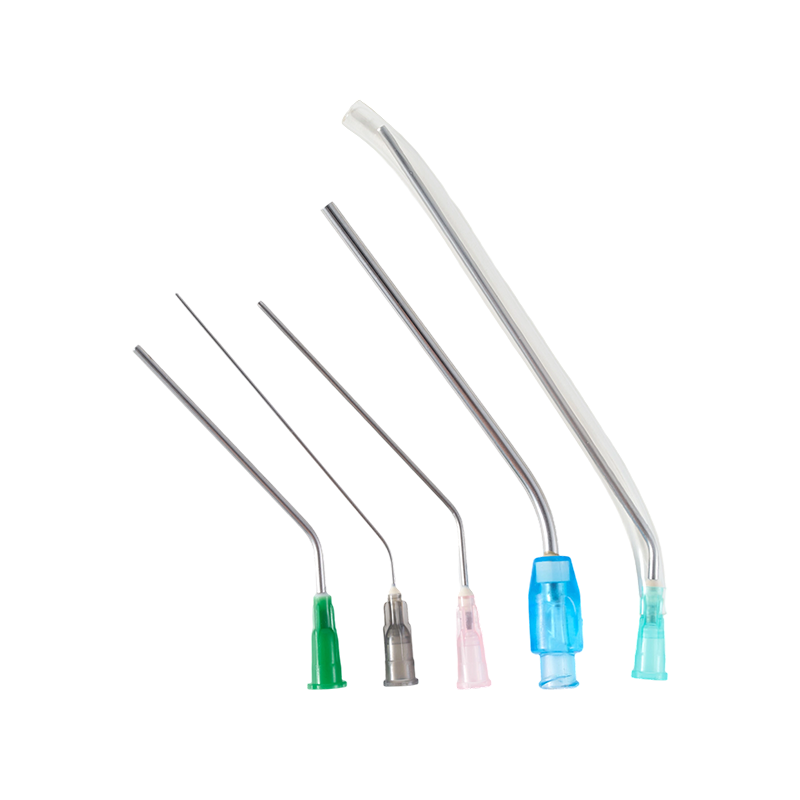

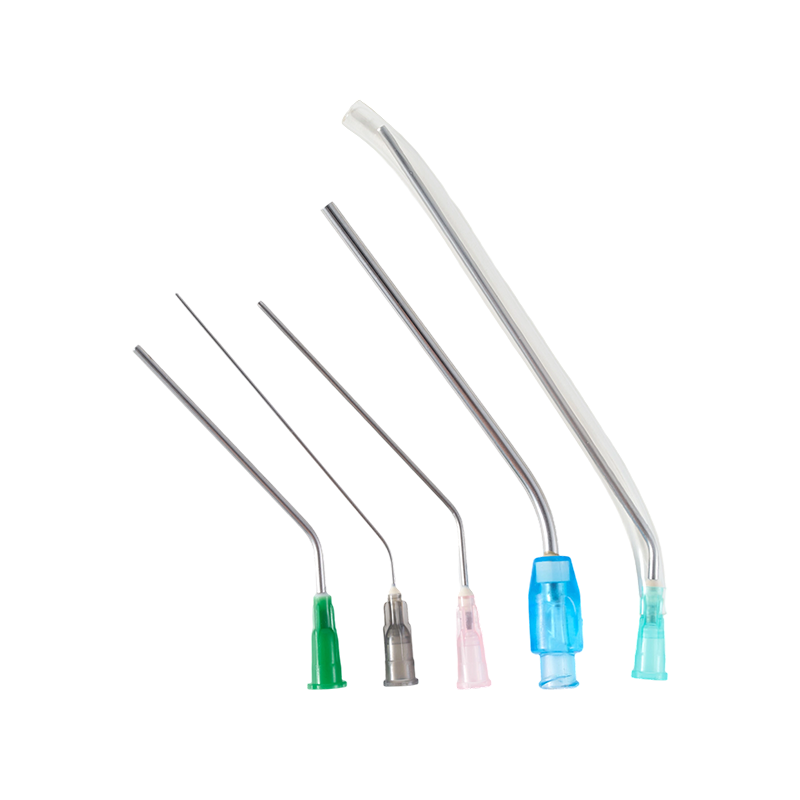

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

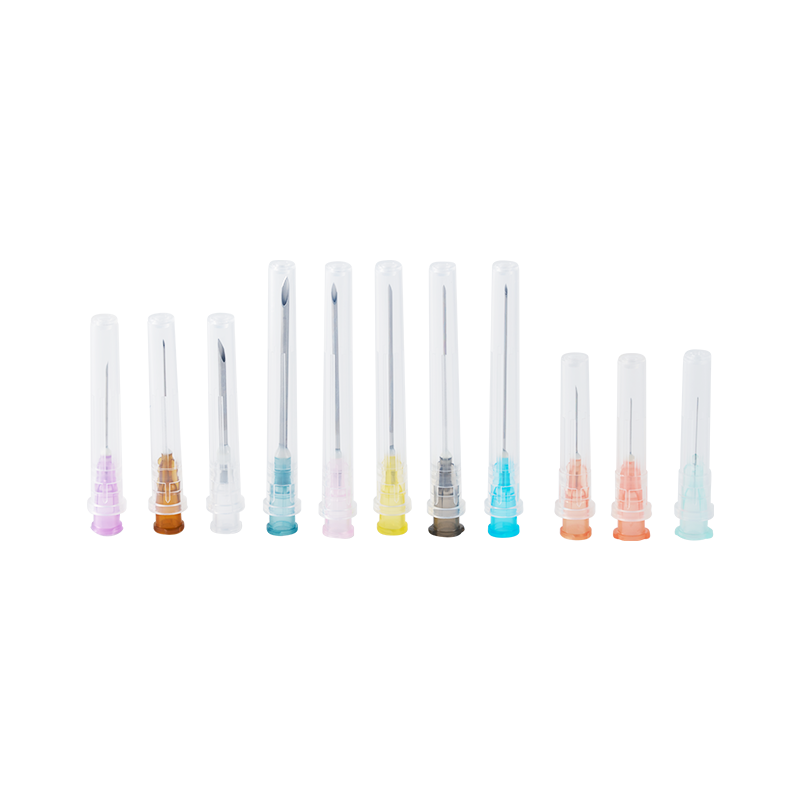

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...