Don't hesitate to send a message

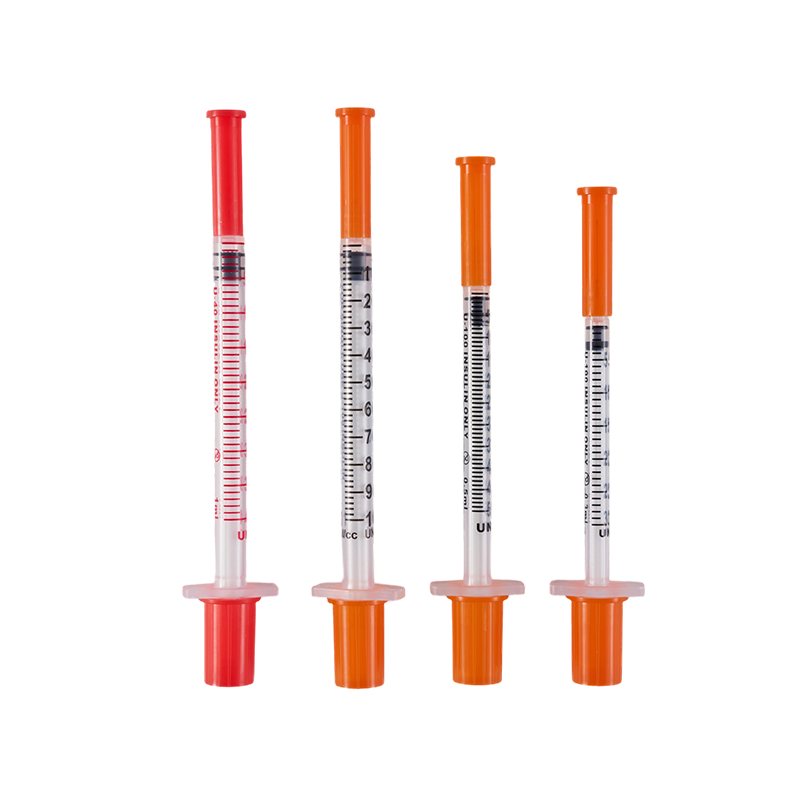

The design and production comply with ISO8537. The plastic parts are moulded by ...

In the field of aesthetic equipment manufacturing, Beauty Injection Needle Suppliers have become key partners for brands and distributors seeking high-quality, precision-engineered components. The Beauty Injection Needle is not a complex instrument in appearance, yet its structure, performance, and consistency depend on meticulous engineering. Behind each product lies a combination of fine materials, great machining, and strict quality systems designed to deliver stable, reliable performance under professional standards.

Every Beauty Injection Needle begins with the selection of medical-grade stainless steel-specifically SUS304 or 304 stainless steel. This alloy is favored for its corrosion resistance, high tensile strength, and excellent biocompatibility. The material is drawn into fine tubing under controlled temperature and tension to achieve uniform wall thickness and smooth internal flow paths.

After forming, the surface of each needle undergoes mirror polishing. This process eliminates micro-burrs and imgreations, producing a smooth surface that allows consistent insertion and controlled delivery. A medical-grade silicone oil coating is then applied to reduce friction and improve overall fluidity.

Professional Beauty Injection Needle Suppliers often operate in cleanroom environments where polishing, cleaning, and lubrication are carried out with precision instruments. The result is a product with low resistance, consistent smoothness, and a visually clean finish that reflects the manufacturer's commitment to detail.

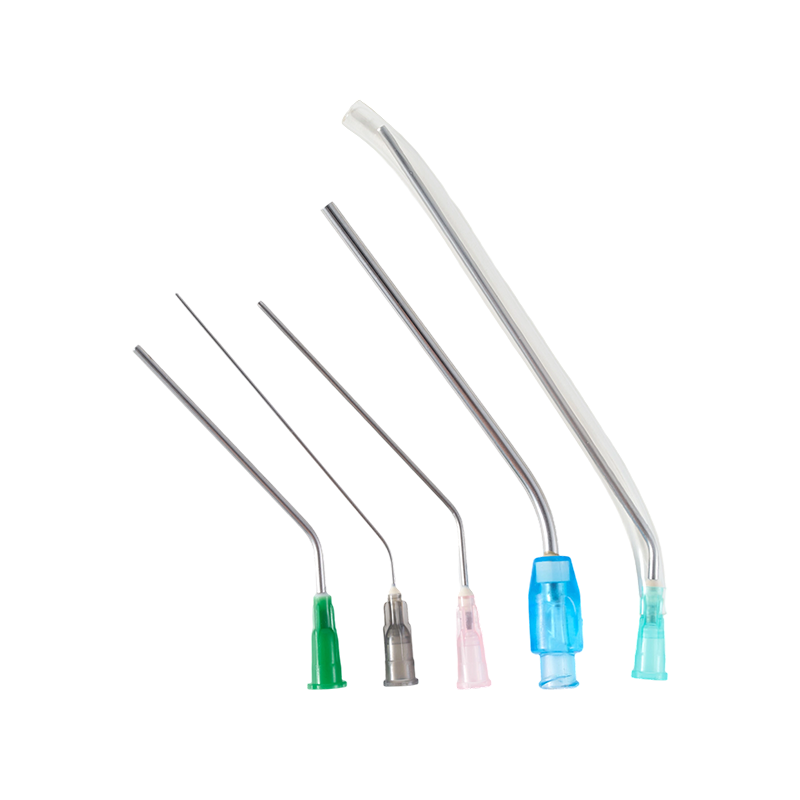

Among the many recognized innovations from Beauty Injection Needle Suppliers is the blunt-end cannula structure. Unlike sharp-tipped needles, these have a rounded, non-cutting end with dual side openings that allow controlled flow of viscous substances. The double-bevel design reduces drag and enhances material distribution efficiency.

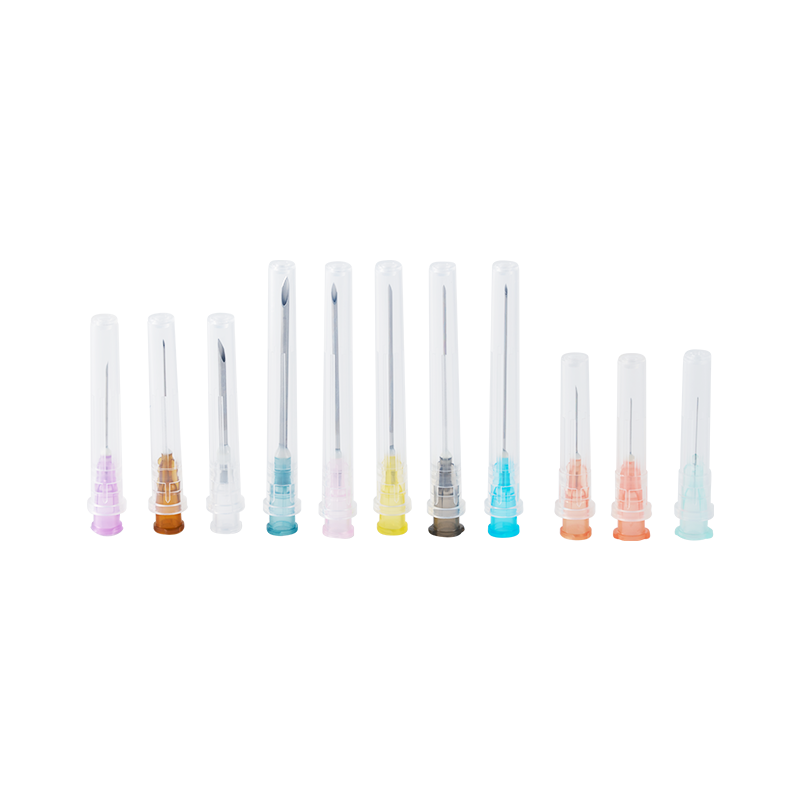

Each Beauty Injection Needle is produced in multiple gauges, typically ranging from 16G to 30G, and lengths from 8mm to 120mm. This wide range ensures suitability for diverse procedural requirements in the beauty and aesthetic sectors.

To achieve dimensional consistency, suppliers use automated CNC machining and optical inspection systems. These machines verify the inner and outer diameters, bevel angles, and length accuracy. Tolerances are often maintained within micrometers, which demonstrates the high level of precision expected in this manufacturing category.

In addition to blunt-end cannulas, Beauty Injection Needle Suppliers produce high-precision microneedles. These tiny structures are crafted using nano-scale puncture technology that shapes ultra-fine tips capable of penetrating the surface layer with minimal disruption. Each microneedle is machined from medical stainless steel and tested for alignment, strength, and uniform sharpness.

The foundation of trust in professional supply lies in manufacturing control. Reputable Beauty Injection Needle Suppliers operate under ISO 13485-certified systems. This international standard outlines strict requirements for medical device production, covering traceability, documentation, and quality management from material sourcing to final sterilization.

Each Beauty Injection Needle is sterilized through EO (ethylene oxide) treatment and sealed in individual packaging to maintain cleanliness and product stability. Batch codes and inspection records allow full traceability for every lot.

Behind every Beauty Injection Needle is an ecosystem of great manufacturing, strict inspection, and technical craftsmanship. From raw steel processing to final sterilization, every step is designed to control quality and repeatability. This attention to microscopic details defines the modern generation of Zhejiang INI Medical Devices Co., Ltd..

The design and production comply with ISO8537. The plastic parts are moulded by ...

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...