Don't hesitate to send a message

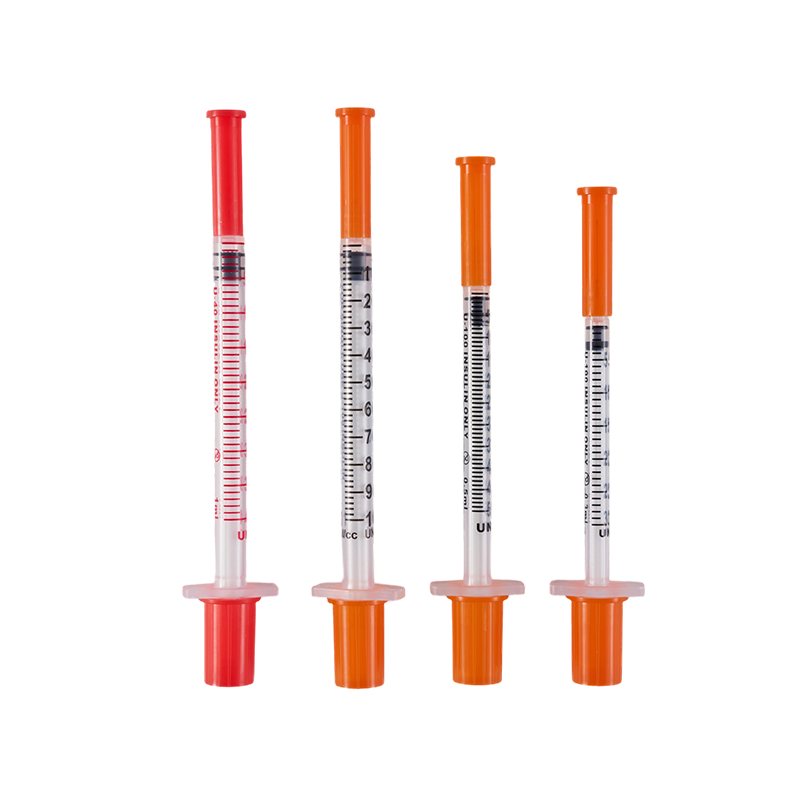

The design and production comply with ISO8537. The plastic parts are moulded by ...

One frequently mentioned concern is the difficulty in aspiration or the presence of resistance during an injection. This can be unsettling for the administrator. When using a Medical Needle, if significant resistance is met when depressing the plunger, it may indicate that the tip is lodged against dense tissue. Similarly, the inability to easily aspirate before an injection, when required by a specific protocol, can be a source of uncertainty. The solution often lies in technique rather than the device itself. A slight repositioning of the Injection Needle, without fully withdrawing it, can often alleviate the issue. Furthermore, selecting the appropriate Medical Needle length and gauge for the patient's anatomy and the medication's viscosity is a critical preventative step. Manufacturers of Medical Needles and Syringes produce a wide array of gauges to accommodate different fluid densities, and choosing the correct one is paramount.

Another common challenge involves the perceived bluntness or discomfort associated with the puncture. The sharpness of every Injection Needle is a key quality parameter meticulously controlled during production. A sensation of dragging or increased pain can sometimes occur. This is rarely a defect in the Medical Needle itself but can be influenced by patient anxiety and muscle tension. For the administrator, ensuring a swift, confident motion can help. It is also essential to check the packaging integrity before use; a compromised sterile barrier could potentially affect the device. The design of modern Medical Needles and Syringes often includes ultra-sharp, laser-ground points and lubricant coatings specifically engineered to minimize puncture force and enhance comfort.

Issues like leakage, either during or after the injection, are also common queries. This can happen if the Medical Needle is not securely attached to the syringe barrel, allowing a small amount of medication to escape from the connection point. The simple solution is to ensure a firm clockwise twist to secure the Injection Needle onto the luer lock hub before the procedure begins. Post-injection leakage from the puncture site can be managed by applying gentle pressure with a dry sterile gauze for a few moments after the Injection Needle is withdrawn. It is a standard practice that should follow the use of any Medical Needles and Syringes.

Needle detachment, though rare, is a concern that has been largely addressed through advancements in device design. In the past, a Medical Needle could theoretically become detached from the syringe inside the tissue during a procedure, particularly if the plunger is forced against a significant blockage. Modern manufacturing standards for Medical Needles and Syringes have made this an extremely uncommon event. Most contemporary Injection Needle hubs are permanently affixed or feature a secure luer-lock mechanism that requires a deliberate twisting action to attach and detach, providing a robust connection that prevents accidental separation. Users are encouraged to visually confirm this secure connection as part of their pre-procedure checklist.

The persistent issue of needlestick injuries remains a top priority in healthcare safety. The moment after the injection, when the used Medical Needle must be disposed of, is a period of high risk. The primary solution is the consistent and correct use of safety-engineered devices. Many modern Medical Needles and Syringes come with integrated safety mechanisms, such as sheaths that slide forward to cover the Injection Needle immediately after use or retractable designs that pull the Medical Needle back into the syringe barrel. These features are integral to the device's design. Alongside this technology, the immediate availability of approved sharps containers and a culture of never recapping a used Injection Needle are non-negotiable safety practices.

Familiarity with the common issues surrounding the use of a Medical Needle—from resistance and leakage to the critical importance of sharps safety—empowers healthcare providers and patients to navigate procedures with greater confidence and competence.

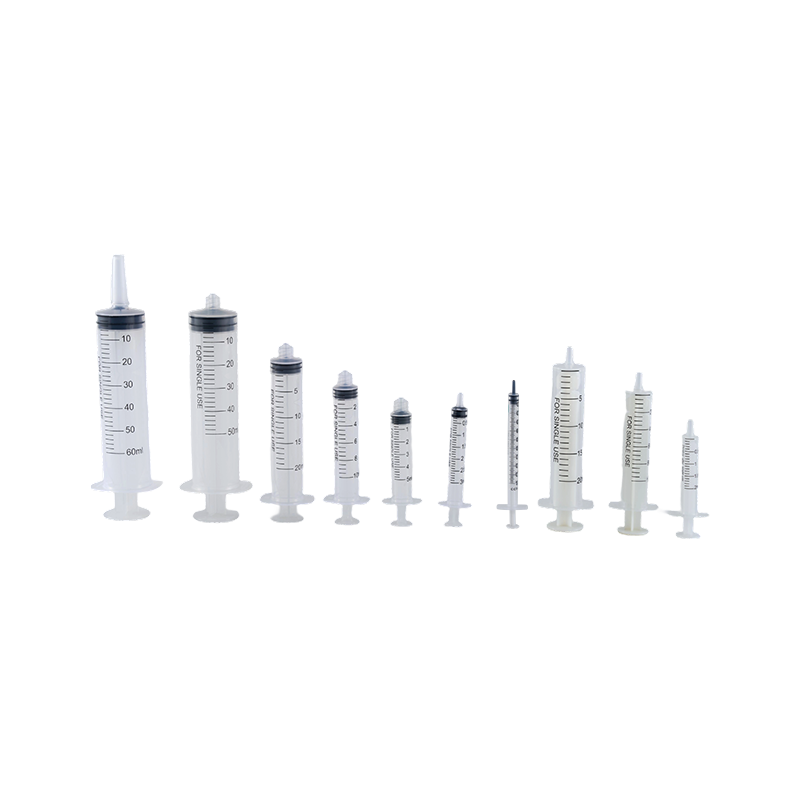

The design and production comply with ISO8537. The plastic parts are moulded by ...

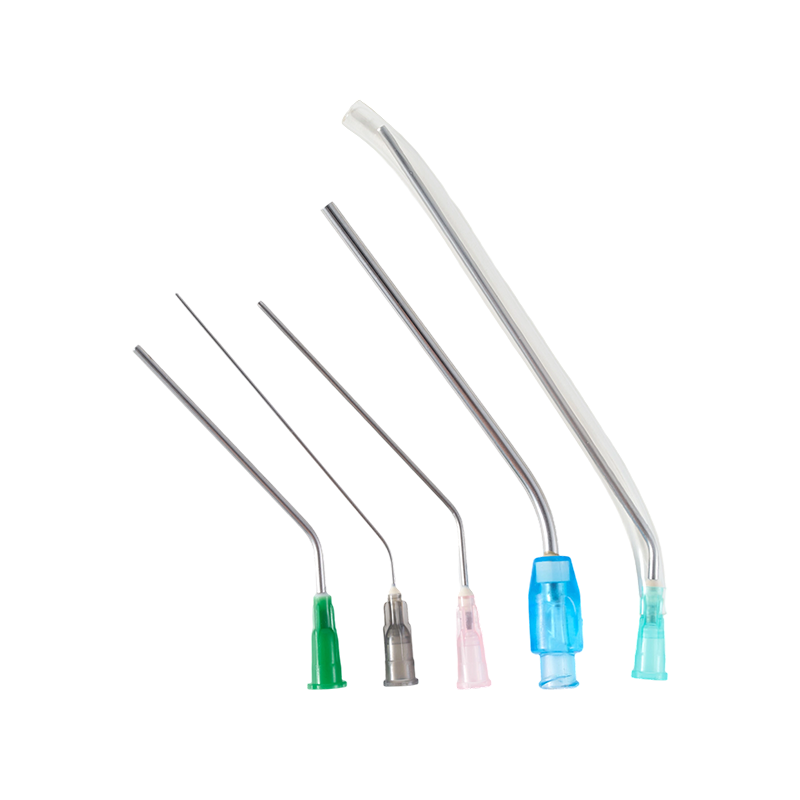

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

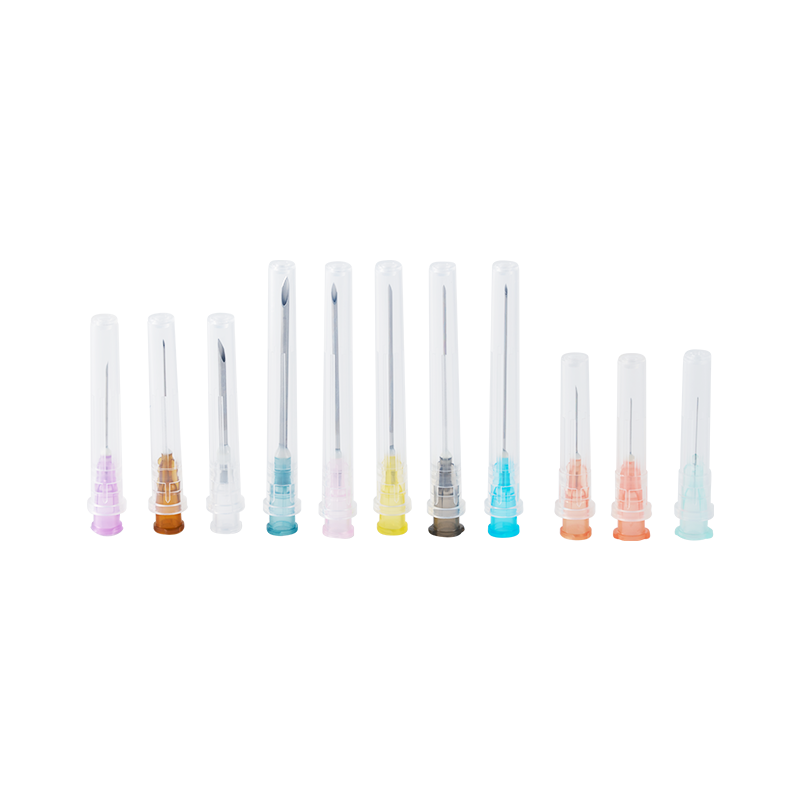

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...