Don't hesitate to send a message

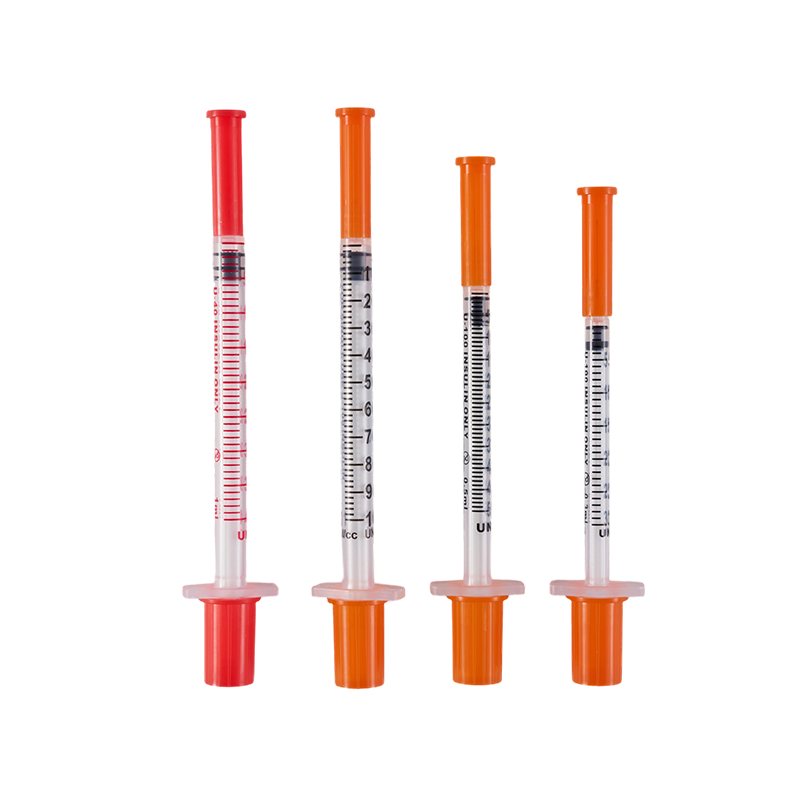

The design and production comply with ISO8537. The plastic parts are moulded by ...

For manufacturers in the medical aesthetics industry, understanding the structural and functional differences between a Pen Lip Filler and a conventional syringe is essential for product innovation and safety assurance.

The Lip Filler Pen operates through mechanical pressure rather than a needle injection. It uses a spring or air compression mechanism to deliver filler material into the upper layers of the skin. This differs greatly from traditional syringes, which require manual control and insertion through a needle.

Manufacturers of Hyaluronic Acid Lip Fillers Pen have refined this design to ensure accurate and consistent flow, reducing the risk of material waste during use. From an engineering standpoint, the Pen Lip Filler offers a needle-free structure, which has become a focus for many beauty product developers.

High-quality materials are critical in both devices. A Lip Filler Pen typically consists of medical-grade stainless steel, ABS, or aluminum components that withstand repeated sterilization. In comparison, syringes rely on polymer bodies and stainless-steel needles. Manufacturers producing Hyaluronic Acid Lip Fillers Pen focus on durability, ease of cleaning, and precision machining to guarantee consistent pressure output.

As industry standards rise, each Pen Lip Filler is tested for mechanical performance, ensuring smooth operation and consistent filler delivery.

One of the most distinct differences lies in the application method. The Lip Filler Pen distributes filler material through high-pressure diffusion, resulting in a more even spread across the surface area. Traditional syringes, on the other hand, require manual insertion depth control by practitioners.

In manufacturing, Hyaluronic Acid Lip Fillers Pen models are designed to deliver accurate volume per shot, minimizing human error. For producers, achieving balanced pressure release is essential to ensure each Pen Lip Filler performs reliably across multiple uses.

Patients and practitioners both value comfort and convenience. The Lip Filler Pen is often seen as more approachable due to its needle-free design, reducing procedural anxiety. Meanwhile, traditional syringes offer more direct control but require higher skill levels for precise results.

Aesthetics equipment manufacturers develop Hyaluronic Acid Lip Fillers Pen tools with ergonomic grips and user-friendly interfaces, improving handling comfort. Each Pen Lip Filler model undergoes multiple design iterations to ensure balanced weight and easy operation.

Comparison Table: Lip Filler Pen vs. Traditional Syringe

| Feature | Lip Filler Pen | Traditional Syringe |

| Delivery Mechanism | Uses spring or air pressure | Manual plunger with needle |

| Design | Needle-free | Needle-based |

| Material Usage | Even and surface-level distribution | Direct injection into tissue |

| Handling | Easier for beginners | Requires professional training |

| Sterilization | Reusable with proper cleaning | Usually single-use |

| User Comfort | Reduces fear and discomfort | More invasive |

| Control Precision | Mechanically regulated | Fully manual |

| Maintenance | Requires pressure calibration | Minimal maintenance |

The market for Lip Filler Pen devices continues to expand globally as consumers seek non-invasive beauty tools. Pen Lip Filler designs have become more refined, with adjustable volume settings and enhanced material compatibility. Manufacturers of Hyaluronic Acid Lip Fillers Pen are responding to this trend by investing in research, ergonomic improvements, and aesthetic appeal.

In contrast, traditional syringes remain essential for medical-grade applications requiring deep tissue delivery. Both tools have their own purpose, but the Lip Filler Pen highlights a growing trend toward safer, more user-friendly cosmetic instruments.

The Lip Filler Pen represents a technological step forward in the medical aesthetics field. While traditional syringes remain important for certain clinical uses, the Lip Filler Pen offers a new direction for comfort, precision, and user convenience.

The design and production comply with ISO8537. The plastic parts are moulded by ...

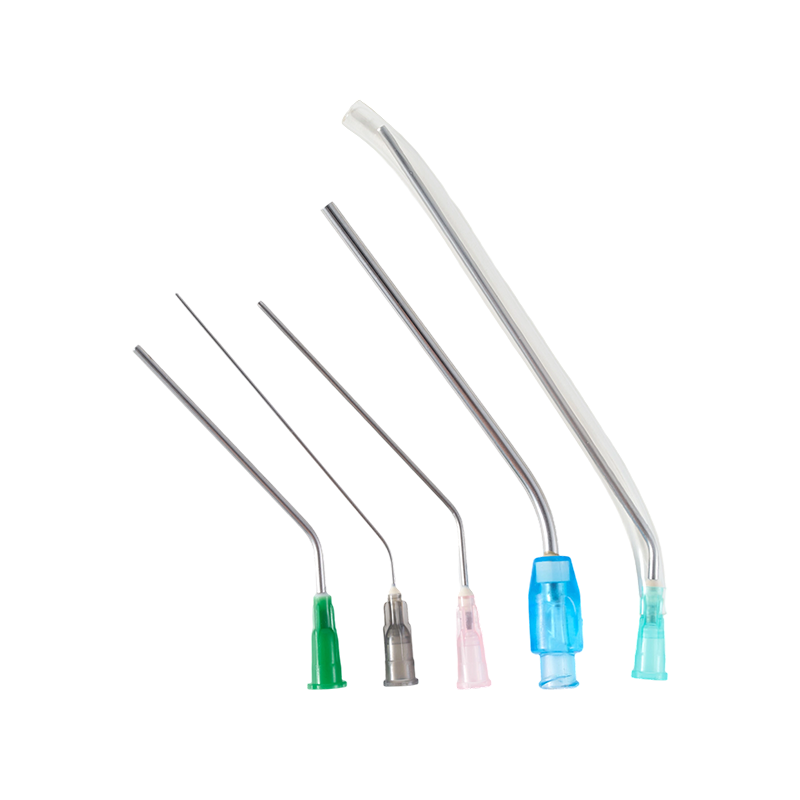

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

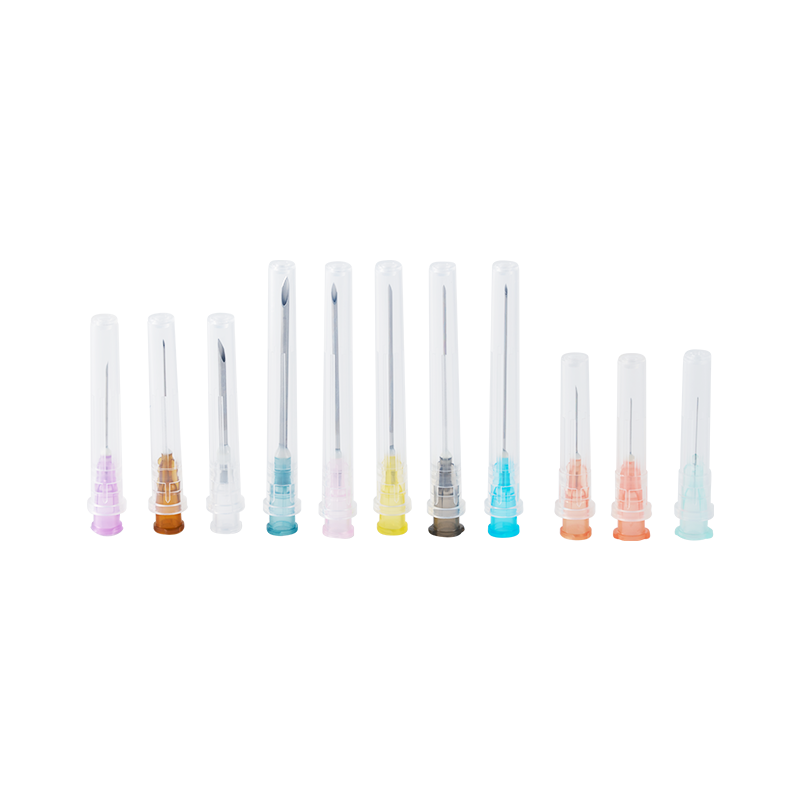

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...