Don't hesitate to send a message

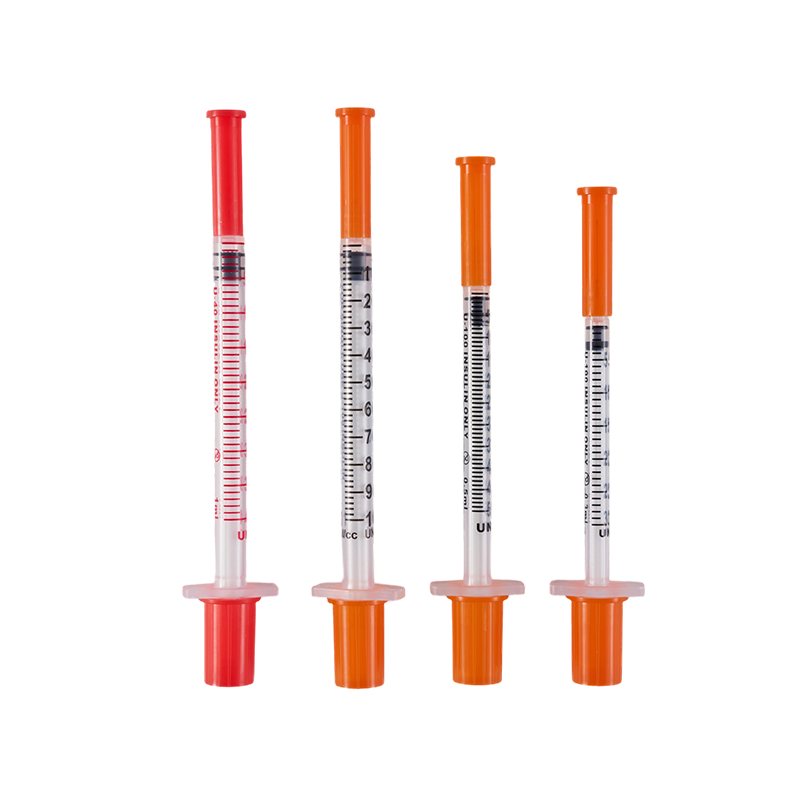

The design and production comply with ISO8537. The plastic parts are moulded by ...

The healthcare industry is witnessing a transformative era in medical device innovation, particularly in the field of injection systems. Recent breakthroughs in Sterile Disposable Needles technology are enhancing patient safety, improving clinical efficiency, and reducing the risk of infections. As global demand for reliable, single-use medical tools grows, advancements in Sterile Injection Needles and Sterile Hypodermic Syringe systems are setting new standards for quality and performance.

Patient safety remains the top priority in healthcare, and today's Sterile Disposable Needles are designed with this goal in mind.

These features make Sterile Disposable Needles a critical tool in infection control protocols.

Precision is essential for effective and painless injections, and modern manufacturing delivers unmatched accuracy.

This level of engineering enhances both patient comfort and clinical outcomes.

The integration of needles with syringes has seen significant improvements in recent years.

These upgrades make Sterile Hypodermic Syringe systems more dependable in critical care settings.

With billions of injections administered annually, consistency in mass production is non-negotiable.

This level of control guarantees that every Sterile Disposable Needles product meets international safety standards.

The pandemic highlighted the need for scalable, safe injection solutions.

These factors make Sterile Hypodermic Syringe systems indispensable in global public health initiatives.

The future holds even more advanced features aimed at improving usability and safety.

As technology evolves, Sterile Injection Needles will continue to play a central role in modern medicine.

Proper storage of Sterile Needles, Blood Collection Needles, and Medical Supplies Needles is a key component of maintaining safety and operational efficiency in healthcare environments. By controlling environmental conditions, preserving original packaging, implementing stock rotation, minimizing direct contact, organizing by type, inspecting regularly, training staff, and using protective transport methods, facilities can effectively prevent contamination and ensure that needles remain sterile and ready for safe handling.

The design and production comply with ISO8537. The plastic parts are moulded by ...

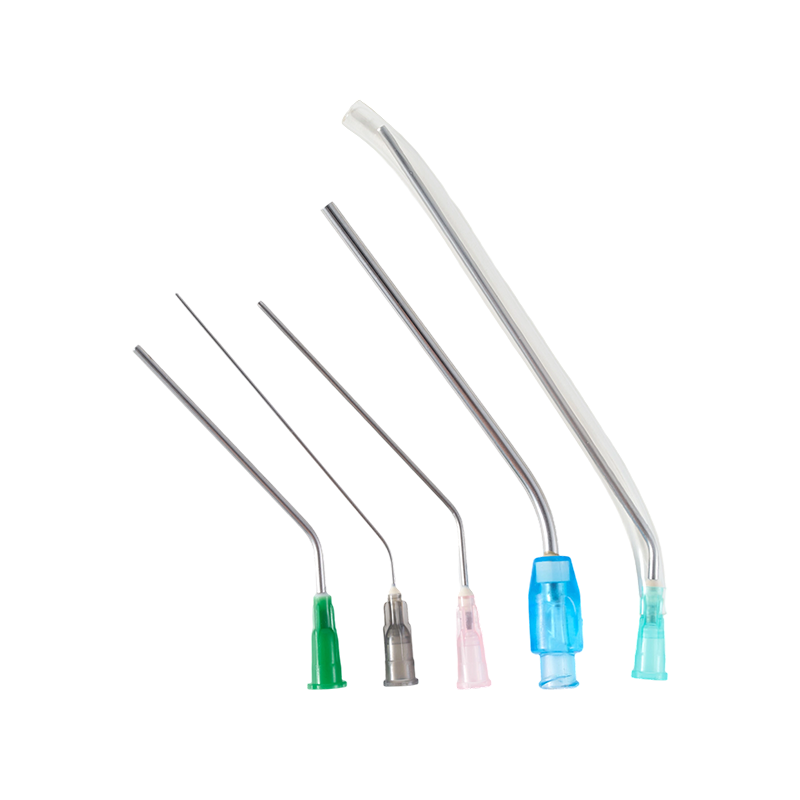

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

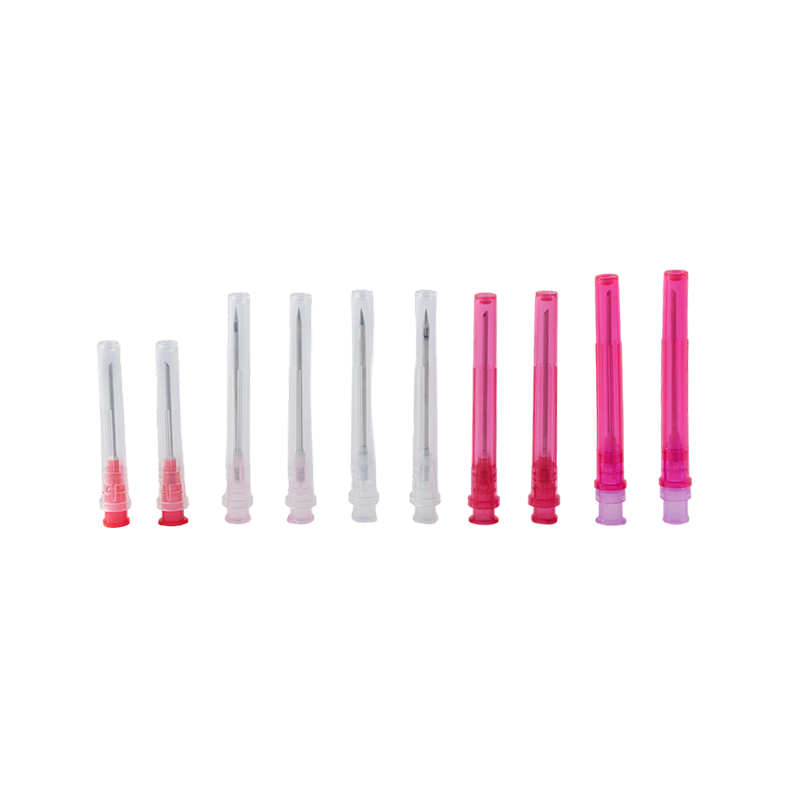

The cannula is made of high quality austenite stainless steel.All the components...

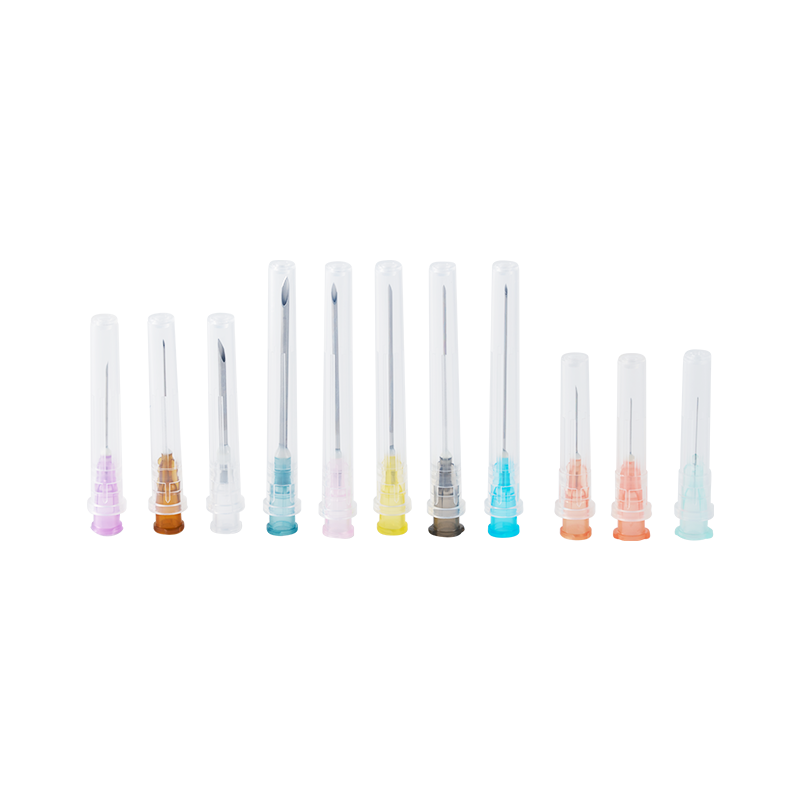

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...