Don't hesitate to send a message

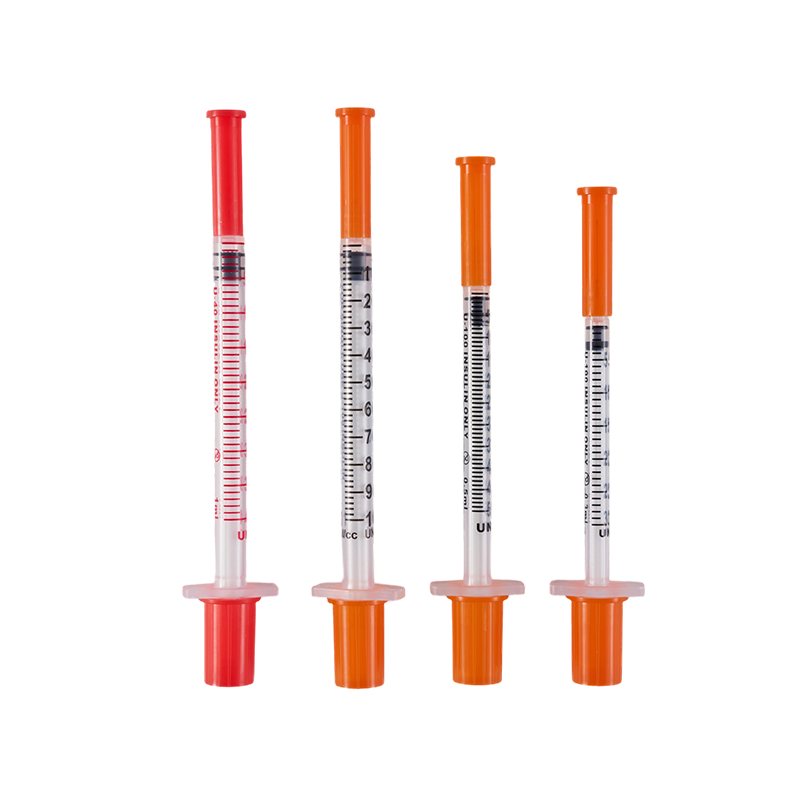

The design and production comply with ISO8537. The plastic parts are moulded by ...

A Syringe And Needle Producer operates at the core of medical injection device manufacturing. These factories are not simply assembling parts; they manage material selection, dimensional control, surface processing, and clean manufacturing environments. Clinics and pharmaceutical companies depend on stable product behavior, predictable fluid delivery, and compatibility with existing systems.

In daily use, syringes and needles must work smoothly together. Any mismatch between barrel tolerance, plunger seal behavior, or needle hub geometry can affect dosing accuracy. This is why production experience and integrated manufacturing matter in this field.

A Syringe And Needle Producer Manufacturer typically covers both syringe bodies and needle elements within one coordinated workflow. Syringe barrels are injection molded using medical-grade polypropylene or similar polymers. Plungers are fitted with elastomeric seals designed to slide consistently inside the barrel while maintaining a closed fluid path.

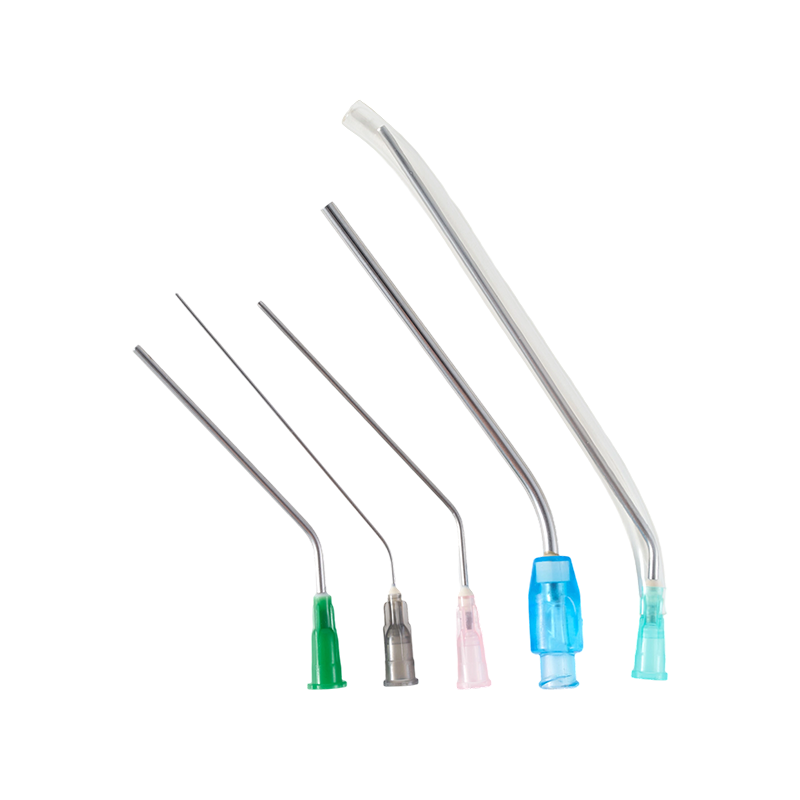

On the needle side, stainless steel tubing is drawn, annealed, straightened, and cut into precise lengths. Bevel grinding and polishing define penetration behavior and consistency across batches. A Syringe And Needle Producer Manufacturer aligns these two production streams so that the needle hub and syringe tip connect without play or leakage.

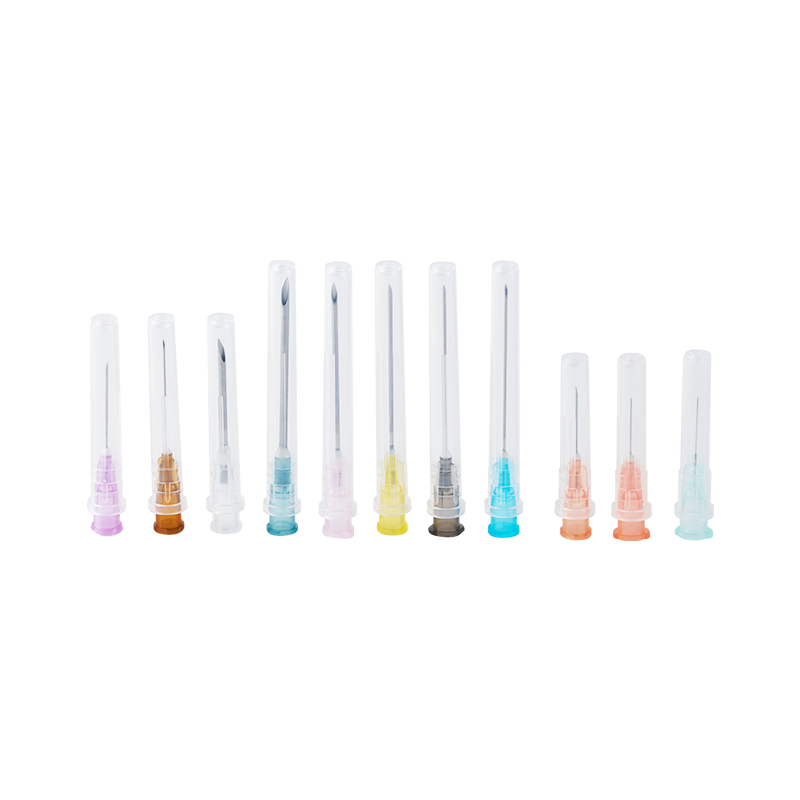

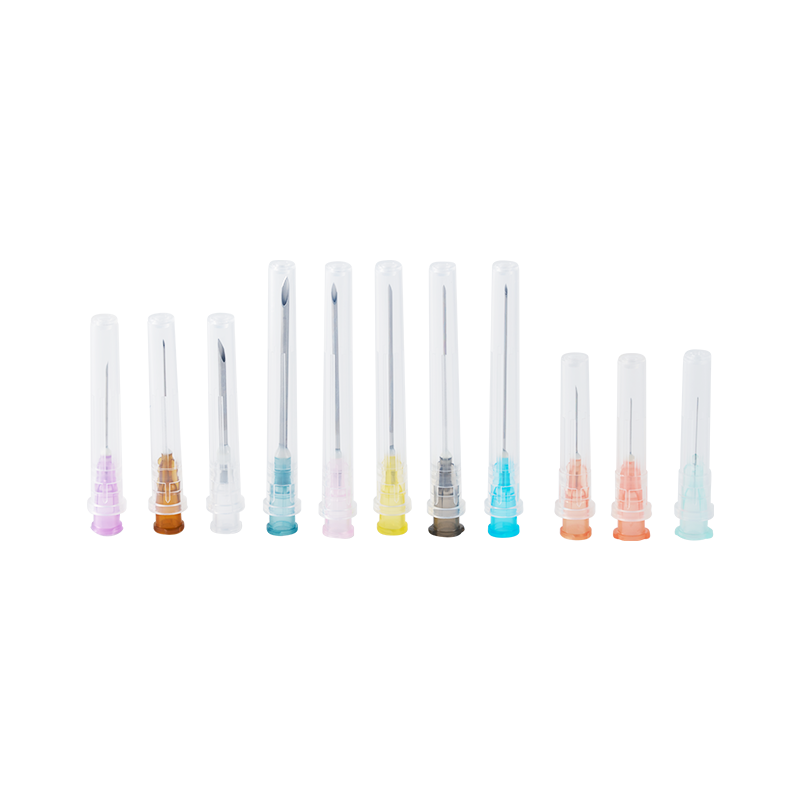

Gauge accuracy is a frequent concern for healthcare professionals. Variations can affect flow rate and penetration feel. As Medical Needle Suppliers, integrated producers fabricate needles across a wide range of gauges such as 18G through 30G. Length options are adjusted based on clinical use, from short micro-needle formats to standard half-inch or one-inch designs.

Each gauge requires separate tooling and inspection standards. A Syringe And Needle Producer maintains dedicated processing parameters for each size to keep dimensional variation within defined ranges.

Compatibility with common connection standards is another pain point in the market. Luer slip and Luer lock designs dominate current syringe systems. A Syringe And Needle Producer Manufacturer pays close attention to hub geometry, taper angles, and surface finish. These details influence how reliably the needle attaches and stays seated during injection.

Poorly controlled interfaces can result in looseness or fluid seepage. Integrated testing during assembly helps identify such issues before products reach distribution channels.

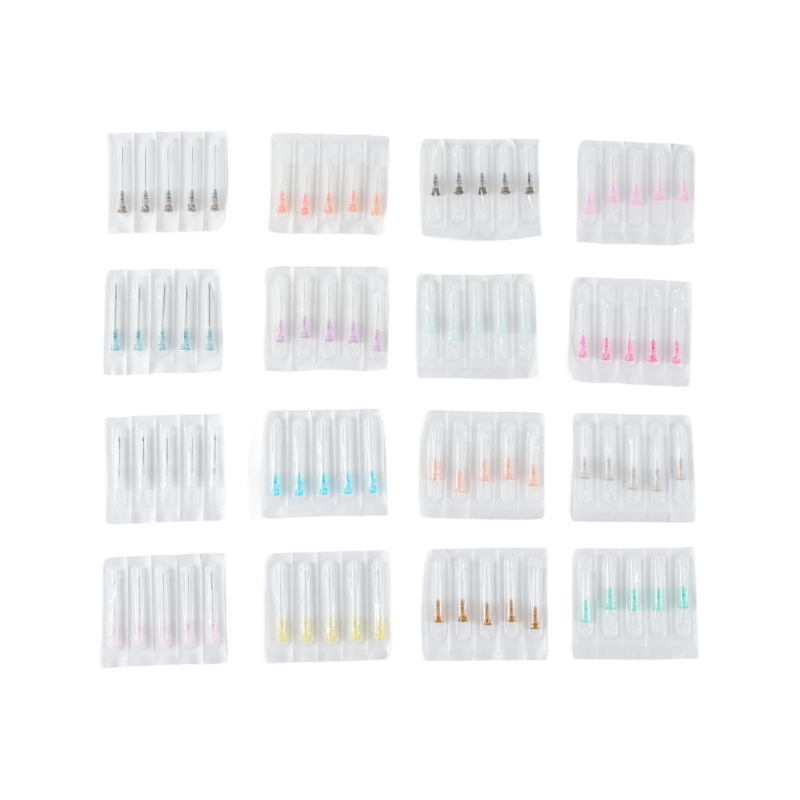

Injection devices are intended for single use, which makes sterile packaging a critical step. After assembly, products are sealed into individual pouches or blister packs under cleanroom conditions. Sterilization methods such as ethylene oxide or gamma radiation are applied under validated cycles.

A Syringe And Needle Producer documents each batch with process records covering assembly, packaging, and sterilization parameters. This traceability supports regulatory review and downstream quality audits without disrupting supply continuity.

Quality control extends across the entire workflow. Dimensional checks confirm barrel volume markings and needle alignment. Functional tests measure plunger movement force and fluid tightness. Visual inspections identify surface defects or misalignment.

As Medical Needle Suppliers, factories also conduct penetration force sampling and cleanliness testing. These steps address real usage concerns raised by clinical staff, such as inconsistent resistance or visible particles.

The design and production comply with ISO8537. The plastic parts are moulded by ...

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...