Don't hesitate to send a message

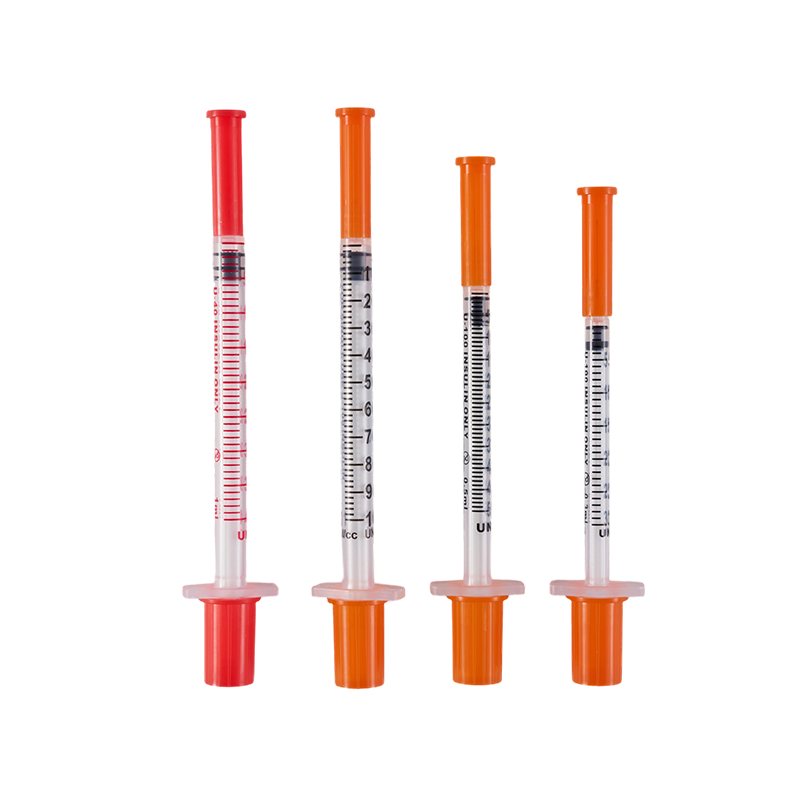

The design and production comply with ISO8537. The plastic parts are moulded by ...

In clinical and laboratory applications, a Hypodermic Needle is a key tool for delivering accurate doses of liquids. Designed for precise fluid transfer, these needles are widely used in medical, pharmaceutical, and research settings. By sourcing from reliable Hypodermic Needle Suppliers, healthcare and laboratory facilities can access products manufactured with consistent specifications and high-quality materials.

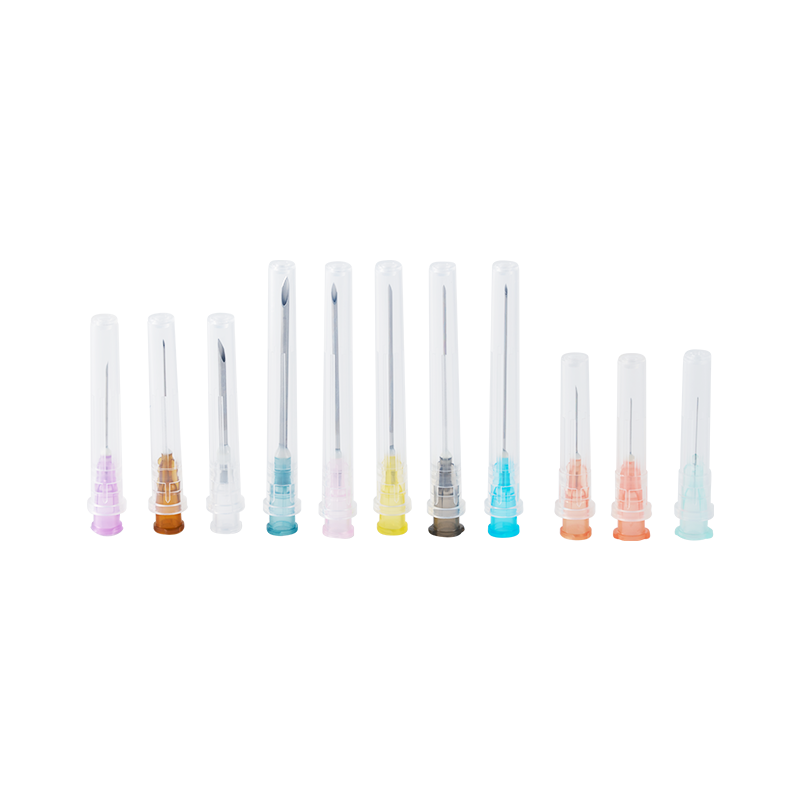

Each Hypodermic Needle begins with medical-grade stainless steel tubing. The tube is drawn to precise diameters, cut to the required length, and ground to create sharp, smooth tips. Bevel angles are carefully controlled to support efficient penetration and fluid delivery. The needle is then attached to an injection-molded hub using ultrasonic or adhesive bonding methods. This design ensures that the needle and hub interface remains aligned during use.

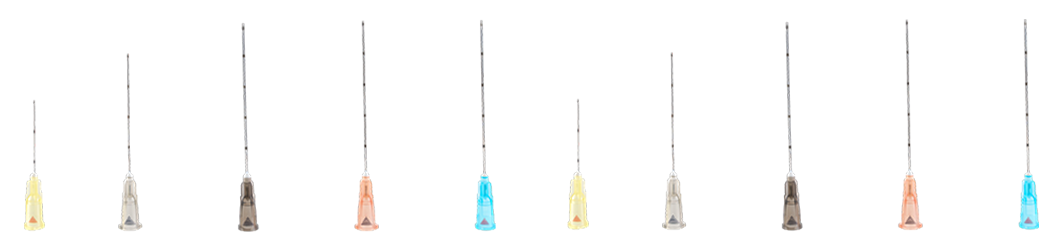

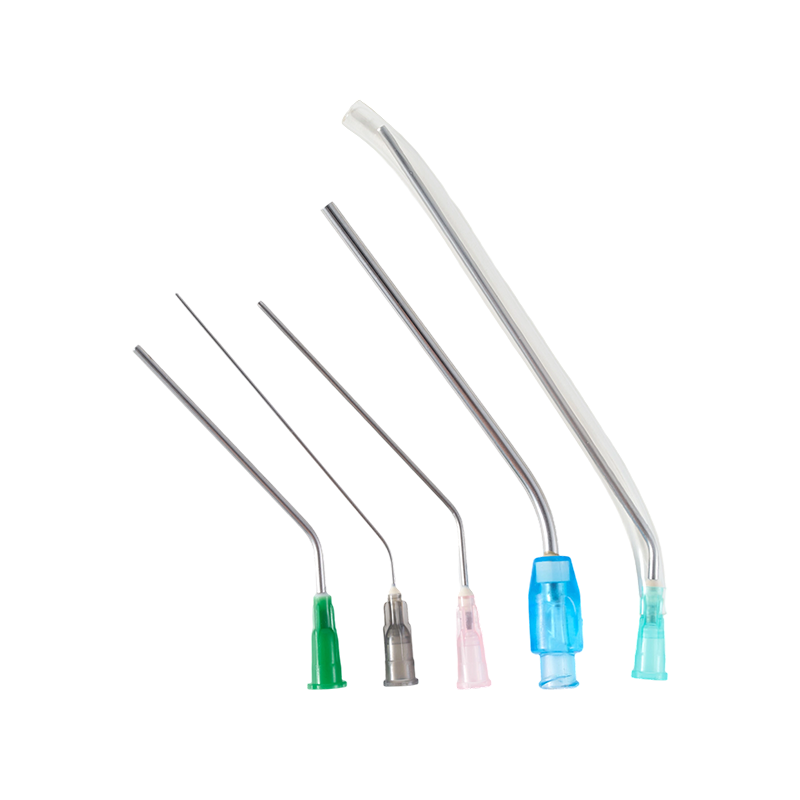

Great tip finishes, such as mirror polishing, reduce friction during insertion. Optional features like protective caps and color-coded hubs assist users in quickly identifying needle size and gauge. These specifications are particularly important for high-volume clinical environments or laboratories where multiple injections occur daily. Hypodermic Needle Suppliers provide these products in a variety of sizes and configurations to match procedural requirements.

The manufacturing process for a Hypodermic Needle involves several critical stages to maintain consistency:

These steps allow Hypodermic Needle Suppliers to deliver products with repeatable performance across batches, supporting clinical and laboratory precision.

Hypodermic needles are available in various gauges and lengths to suit different injection requirements. For example, fine-gauge needles are used in insulin pens or pediatric injections, while longer, wider gauges are applied in fluid sampling or laboratory procedures. Hypodermic Needle Suppliers also offer custom hubs, protective caps, packaging formats, and color coding for workflow optimization.

Clients can request prototypes or OEM/ODM adaptations to match specific equipment or procedural needs. By providing multiple configurations, suppliers accommodate both routine and specialized workflows without compromising design integrity.

A Hypodermic Needle is versatile in its applications. In hospitals, they are used for intravenous injections, vaccinations, and sample collection. In pharmaceutical and research labs, these needles support precise fluid measurements and controlled delivery of reagents. The variety in gauge, length, and tip design allows users to match the needle to the intended procedure, ensuring consistent performance for repeated use.

Hypodermic Needle Suppliers maintain a structured production schedule and supply chain to meet global demand. Raw materials for common needle models are stocked, and multiple suppliers for critical components are qualified to maintain production continuity. Automated assembly lines and in-house sterilization facilities streamline manufacturing and packaging, while final inspection confirms dimensional accuracy, tip alignment, and packaging integrity.

The design and production comply with ISO8537. The plastic parts are moulded by ...

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

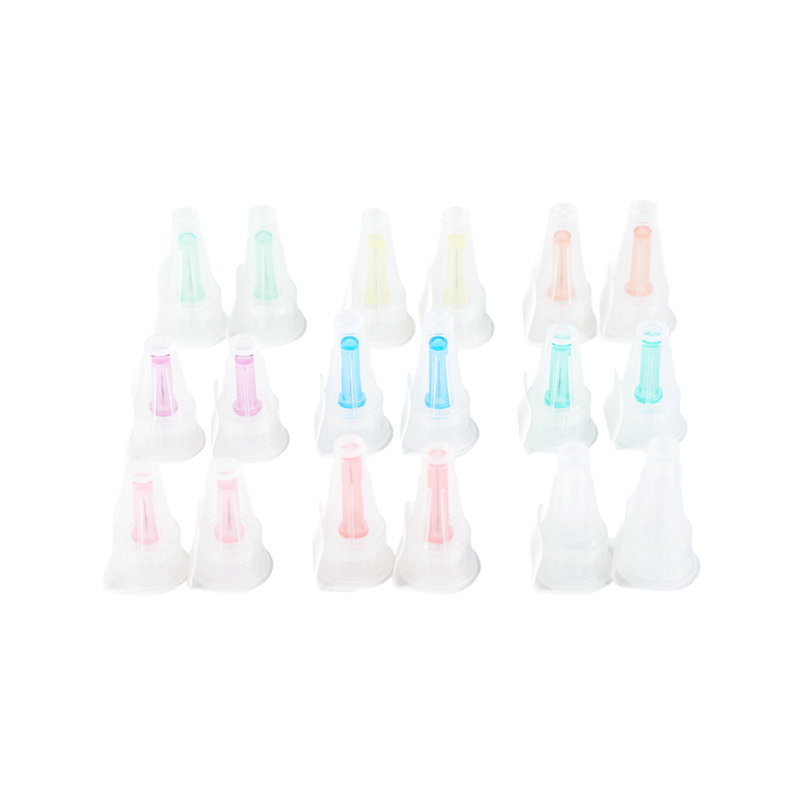

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...