Don't hesitate to send a message

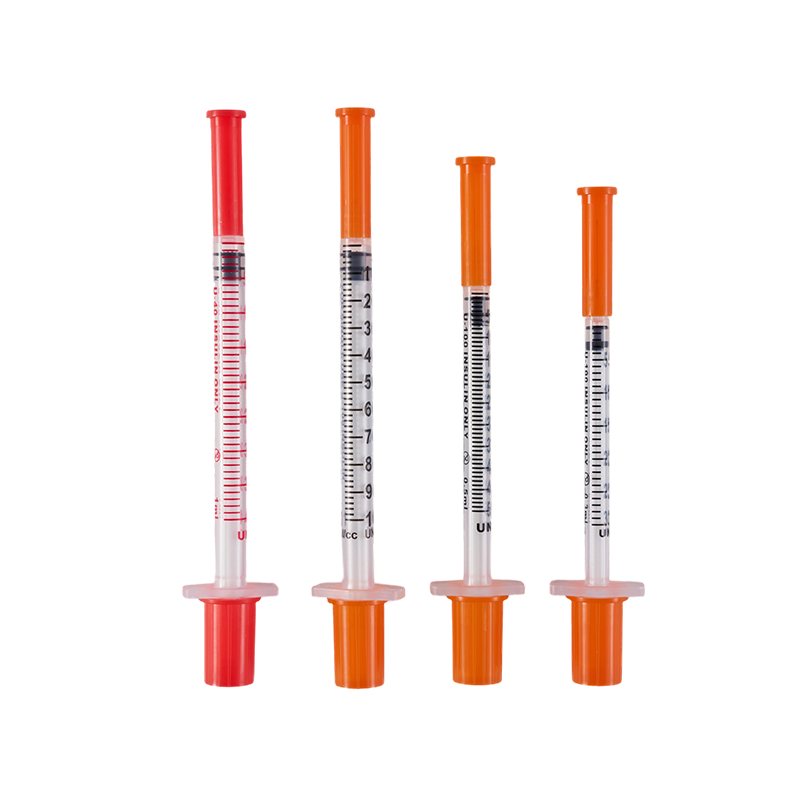

The design and production comply with ISO8537. The plastic parts are moulded by ...

Procurement teams working with syringes and injection needles often look for stable partners who can handle technical requirements, clear production workflows, and predictable delivery cycles. For many buyers, the real questions center around performance, consistency, and whether the supplier can support long-term projects without production gaps.

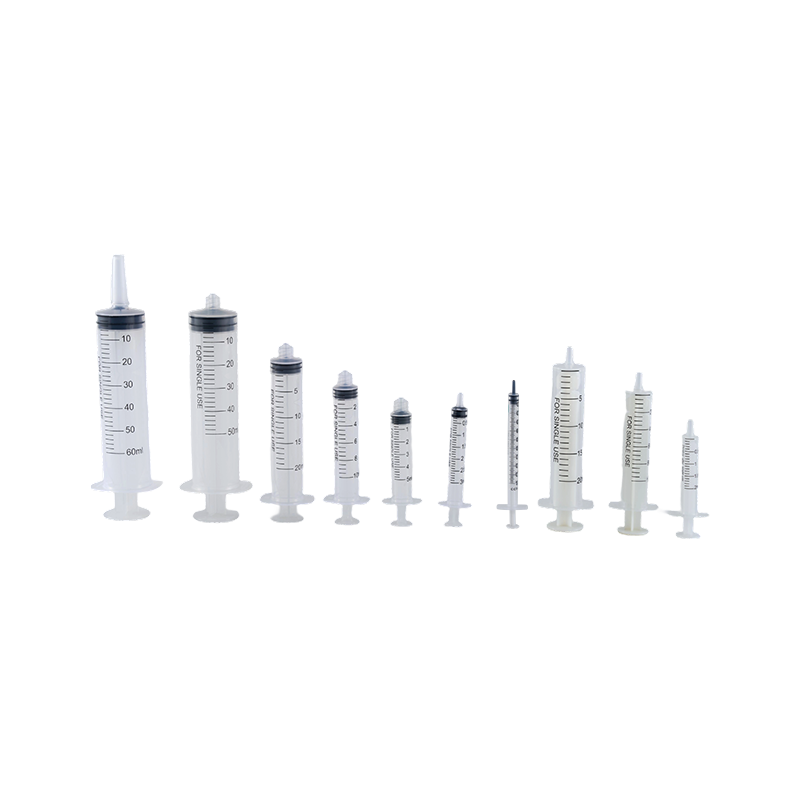

Buyers frequently struggle with inconsistent product quality when dealing with unknown suppliers. A supplier with integrated syringe and needle capabilities provides better uniformity from molding to needle polishing. Using medical-grade polypropylene and controlled elastomer seals, the barrel and plunger system stays smooth during fluid movement and avoids leakage. The dosage scale, printed with clear markings across 0.1 ml to 60 ml, allows precise reading during clinical use.

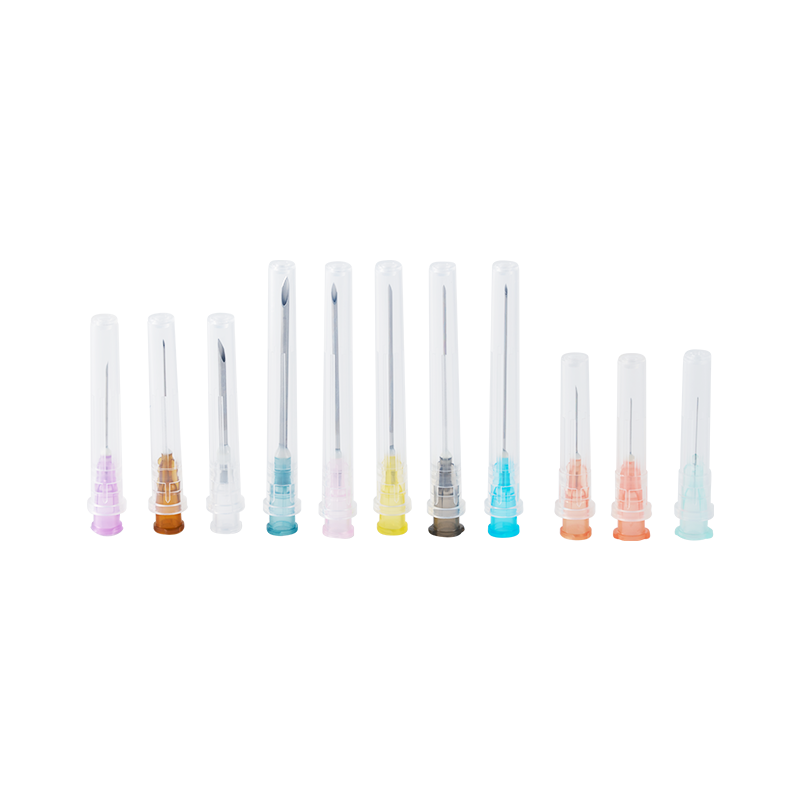

A strong production line also means the needle element is manufactured with predictable gauge and bevel specifications. When Medical Needle Suppliers grind and polish the bevel using laser finishing, the puncture becomes smoother, which reduces discomfort for patients and supports vaccination programs with higher throughput. This level of detail is seldom visible to end users, but it matters to purchasing teams who must justify selection decisions.

Procurement teams often deal with delays caused by unclear manufacturing schedules. When a factory handles needle tube drawing, hub molding, injection molding, assembly, and packaging under one workflow, communication becomes easier.

For example, the stainless-steel tube goes through drawing, cutting, beveling, and polishing before it is bonded to the molded hub by ultrasonic or laser welding. When these steps are executed in the same facility, lot-to-lot stability improves, and buyers have a clearer understanding of cycle times.

Medical Needle Suppliers operating cleanroom packaging lines also provide better control of sterilization cycles using ethylene oxide. For hospitals and distributors, this reduces the chance of receiving incomplete documentation or inconsistent sterilization validation, which can create administrative delays.

Many procurement teams face mismatched components when sourcing needles and syringes from different factories. A supplier offering both components simplifies this challenge, especially when the connection interface follows standard Luer slip or Luer lock geometry.

Some buyers also require unique gauge-length combinations, color-coded hubs for quick selection, or low dead space designs for sensitive dosing applications. Medical Needle Suppliers that provide these options reduce the need for multiple vendors and cut down the risk of incompatibility.

For pharmaceutical filling lines, the availability of smooth, polished needles and stable syringe barrels supports repeatable dosing without clogging or leakage. When special packaging formats such as blister packs, trays, or multi-packs are needed, integrated producers can switch formats with fewer tooling adjustments.

One common pain point is receiving goods with compromised packaging or unclear QC records. A triple-sealed sterile pouch protects the device during transport and reduces the chance of cross-contamination. Each batch comes with documentation covering penetration force tests, leak checks, plunger movement, package integrity, and sterility results.

Medical Needle Suppliers today do more than provide standard products. They support smoother procurement, stable quality lines, and better compatibility for different clinical and pharmaceutical environments. For buyers aiming for dependable supply and clear communication, choosing an integrated producer becomes a practical long-term decision.

The design and production comply with ISO8537. The plastic parts are moulded by ...

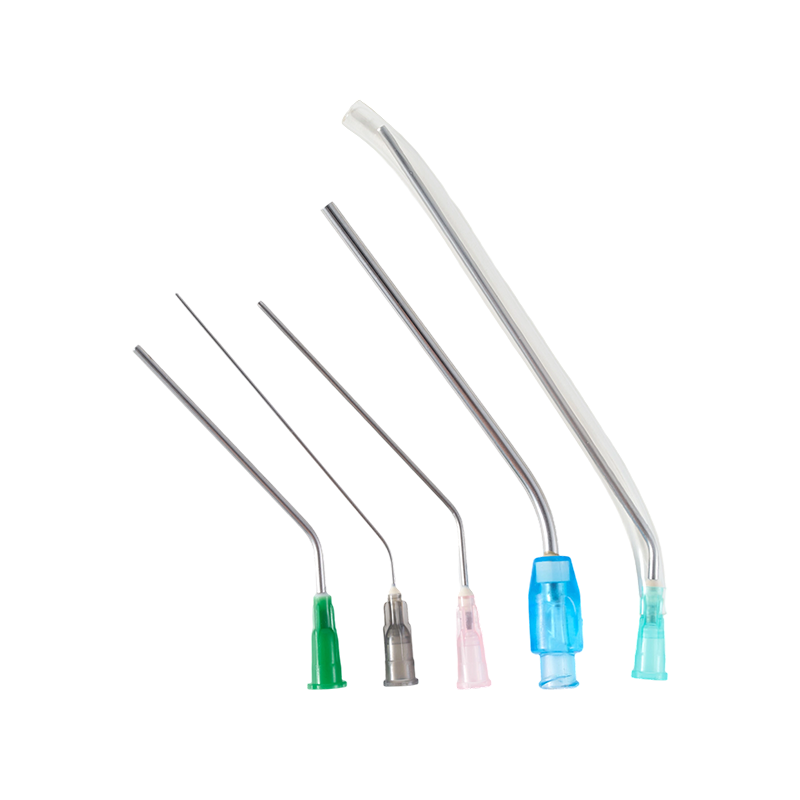

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...