Don't hesitate to send a message

The design and production comply with ISO8537. The plastic parts are moulded by ...

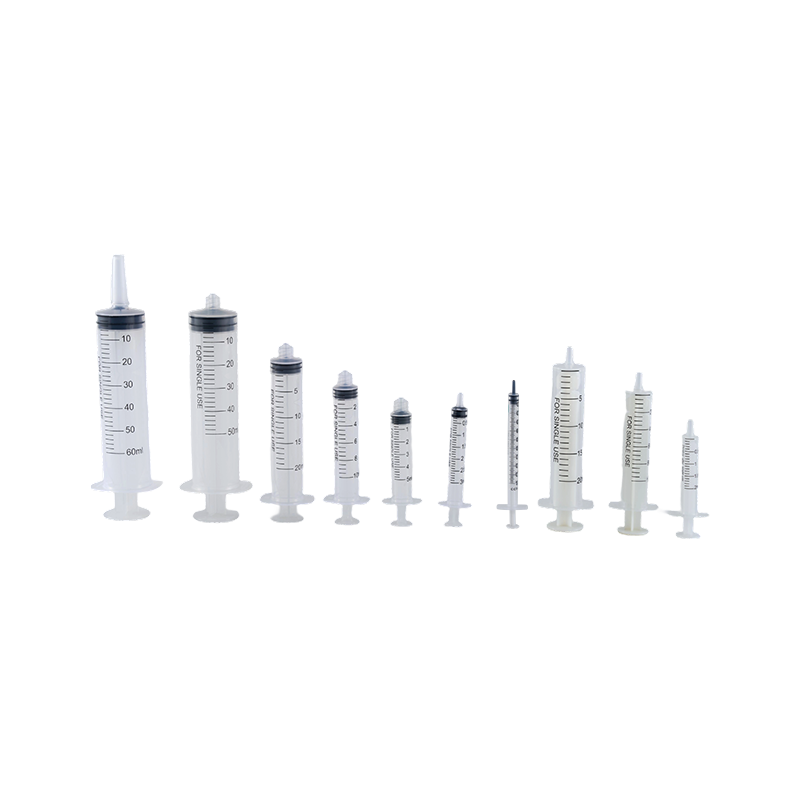

Healthcare facilities, laboratories, and distributors rely heavily on predictable and clean injection products, and the Disposable Syringe plays a steady role in this supply chain. Procurement teams need clarity on quality, performance, and hygiene, especially when handling high-volume orders.

Buyers often question whether a Disposable Syringe can deliver clear visibility and stable function. A transparent polypropylene barrel helps users see the liquid flow during preparation and injection. Accurate scale markings benefit dosing tasks in hospitals and laboratories, where repeated accuracy matters.

The piston, made from either synthetic or natural rubber, fits the barrel with controlled tolerance. Medical-grade silicone oil supports smooth sliding and good sealing, helping the syringe function consistently during repeated movements. For procurement teams, this reduces complaints from end users and aligns with standard requirements for fluid handling.

Many customers express concerns about contamination risk when sourcing from unfamiliar factories. Automated equipment reduces this concern. When component molding, assembling, and packaging are all done by machines inside controlled rooms, product cleanliness becomes more predictable.

Disposable Syringe Suppliers that follow ISO and GMP production systems also support buyers with stable documentation and traceability. This is especially important for hospitals and distributors handling audits or tender requirements. The controlled workflow gives buyers confidence that the syringe has been produced under consistent conditions.

A clean production environment also helps reduce variations in piston movement, leakage complaints, and scale visibility issues, common problems seen when sourcing from factories with less structured processes.

Different application environments require different packaging solutions. A Disposable Syringe in blister packaging helps maintain sterility for clinical injection rooms, while bulk packaging is useful for labs and distributors handling high-volume repackaging. Being able to switch between these formats makes planning easier for procurement teams.

Customization is another key point. Some buyers need printed logos, needle combinations, or specific syringe volumes. Disposable Syringe Suppliers offering flexible configurations save customers from purchasing separately from multiple vendors. This also supports smoother logistics, as syringes and needles arrive matched and ready for use.

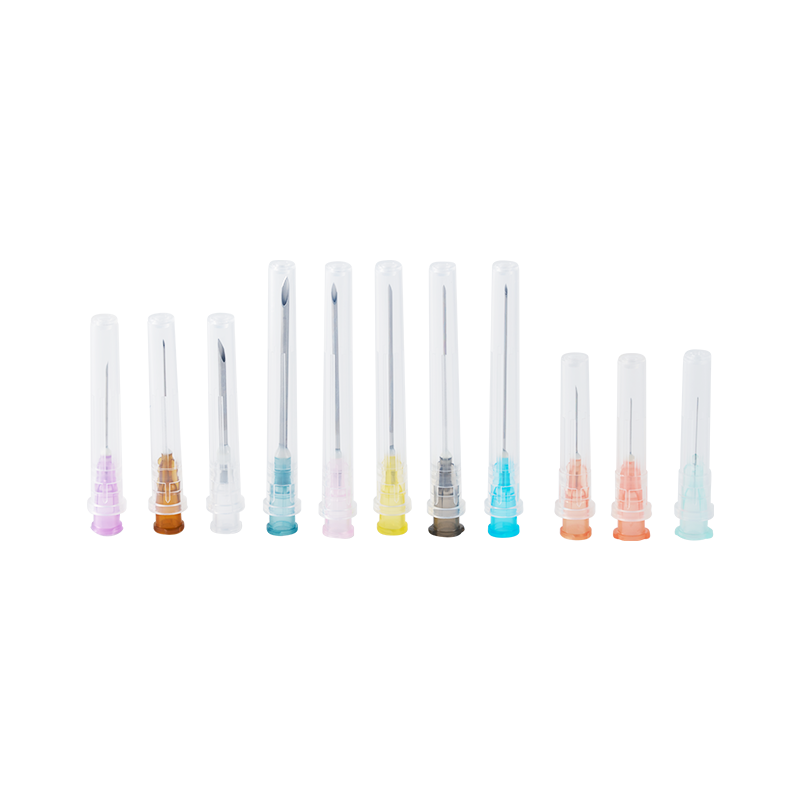

Large-volume buyers often request different needle gauges and lengths to fit their routine injection or laboratory workflows. Matching stainless-steel needles produced under controlled polishing and sterilization conditions helps maintain compatibility and reduces the risk of receiving mismatched components.

A recurring concern among distributors is inconsistent supply. Disposable Syringe Suppliers with automated lines and controlled production cycles help buyers plan stock more accurately. This becomes important during seasonal demand peaks or when hospitals place urgent requests.

Each syringe undergoes inspection for visual appearance, scale clarity, sealing function, and smooth piston movement. These checks help customers avoid receiving batches with defects that interrupt usage in clinical rooms. Reliable sealing reduces leakage complaints and supports clean operation in both medical and laboratory environments.

Choosing a Disposable Syringe supplier involves evaluating clarity, consistency, and production hygiene. When these factors align, medical teams experience smoother workflow, and distributors reduce the burden of sorting and rechecking incoming goods.

The design and production comply with ISO8537. The plastic parts are moulded by ...

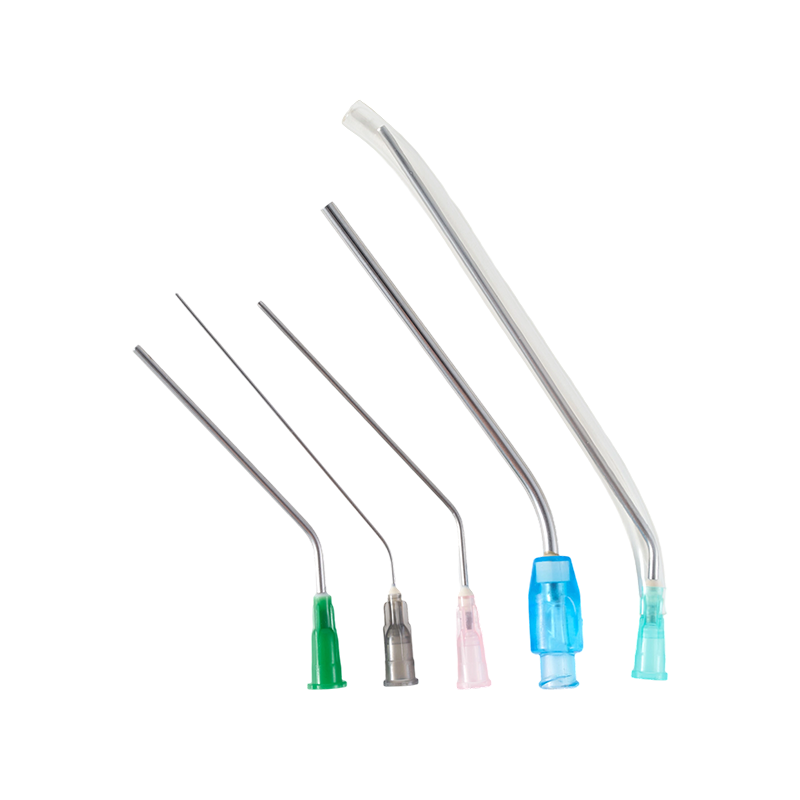

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

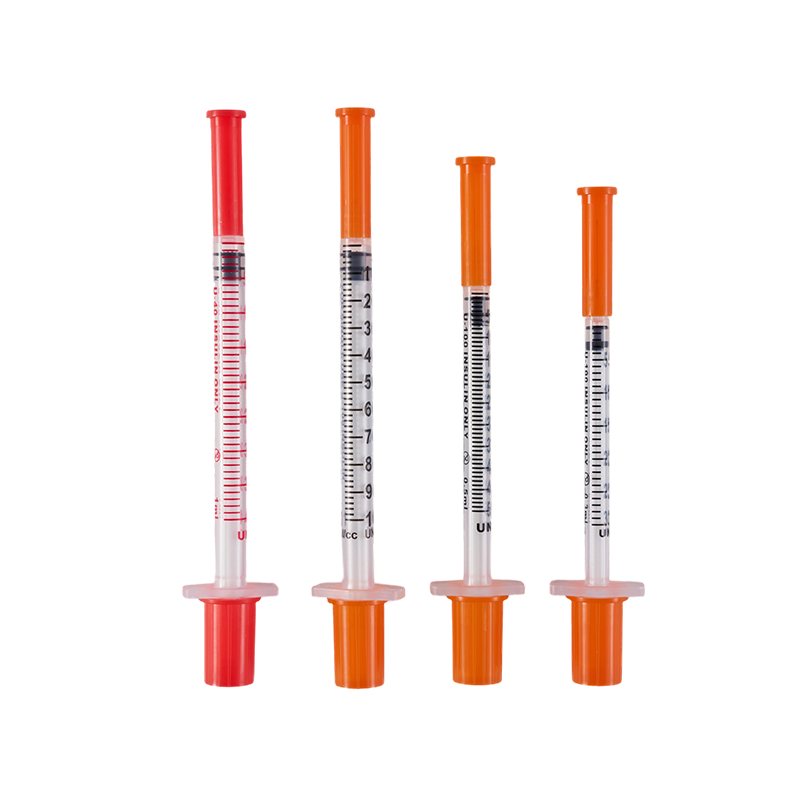

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...