Don't hesitate to send a message

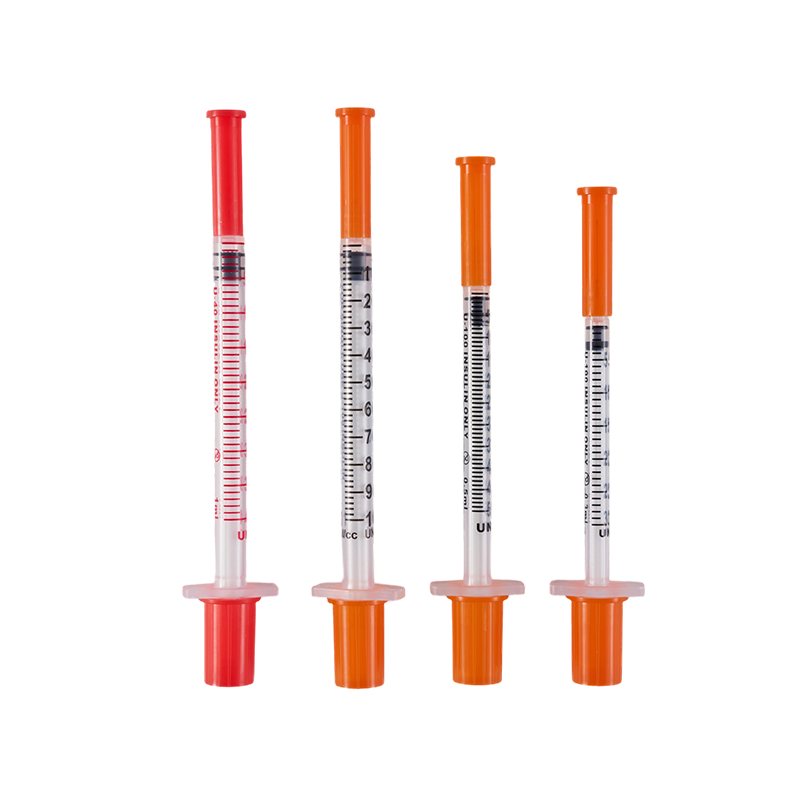

The design and production comply with ISO8537. The plastic parts are moulded by ...

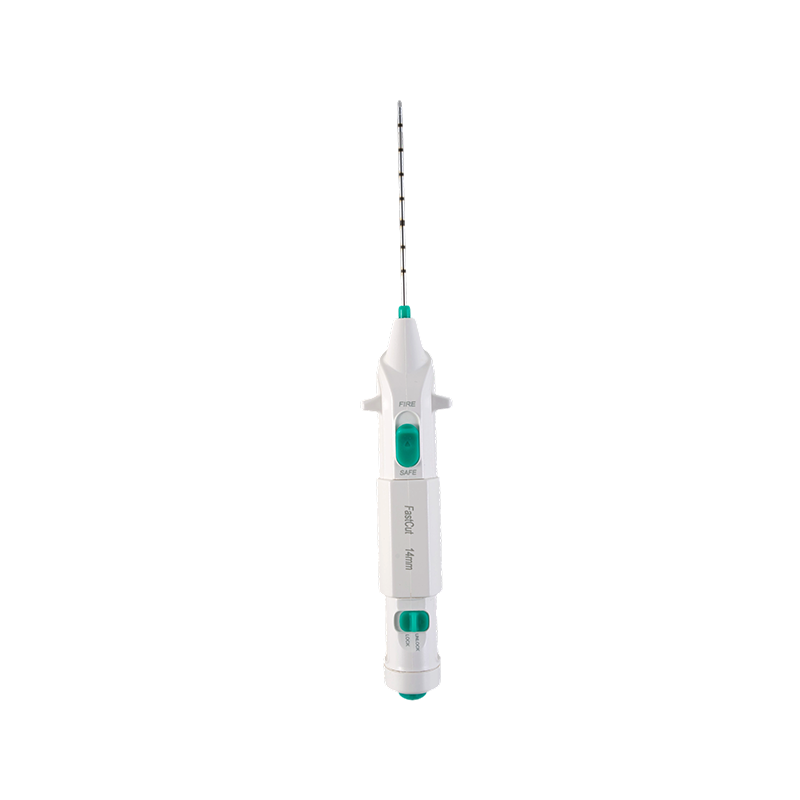

Biopsy procedures demand precision, clean handling, and predictable mechanical action. Hospitals, imaging centers, and device distributors all need biopsy tools that support accurate sampling without disrupting workflow. A Biopsy Needle plays a steady role in diagnostic routines, especially when working under ultrasound or CT guidance. At the same time, Biopsy Needle Suppliers must meet strict requirements for size range, surface finish, and sterile packaging that match clinical expectations.

Clinicians often focus on how well a Biopsy Needle captures tissue without deformation. Using medical-grade stainless steel with micron-level grinding supports smooth penetration and stable cutting. A spring-triggered design with controlled cutting force helps produce consistent sample lengths during liver, soft-tissue, or tumor biopsy work.

The double-bevel tip and mirror-polished surfaces further support precise puncture while lowering resistance. These features help reduce unnecessary movement during insertion, which is important when navigating under ultrasound or CT guidance. Buyers who work with Biopsy Needle Suppliers offering stable bevel geometry and clean internal surfaces often report fewer complaints about sampling irregularities.

Sample integrity matters for diagnosis. When the notch geometry is controlled, and the side groove uses steady adsorption, clinicians can obtain enough material quickly. A Biopsy Needle that collects a usable core in a short operating window allows smoother interaction between imaging and sampling steps.

Hygiene is a core concern during biopsy procedures. That is why Biopsy Needle Suppliers use fully automated environments with aseptic controls. EO sterilization maintains a clean state, while sealed pouches protect the product during transport. Many hospitals request traceability documents, and suppliers working with ISO 13485 systems can provide clear batch records.

Triple epoxy sealing film packaging adds stability during storage. This is helpful for imaging centers that stock many sizes, including 14G, 16G, 18G, and 20G. Reliable packaging reduces the risk of damage that could interrupt procedures or create unnecessary waste.

Clinicians often deal with tissue at different depths and from different organs. A broad range of gauges and lengths helps match biopsy tasks more accurately. Some procedures require longer shafts, while others rely on shorter, more controlled insertion. Biopsy Needle Suppliers who offer depth markings, color-coded hubs, and consistent cannula dimensions help clinicians locate target tissue with more confidence.

The fit between the stylet and the cannula also matters. A well-matched set prevents wobble and improves the clean capture of tissue inside the specimen notch. The smooth action of the trigger mechanism supports controlled sampling, whether the clinician is performing a liver biopsy, lymph node biopsy, or soft-tissue extraction.

Device integrators and OEM clients often request special hub shapes, proprietary markings, or variations in specimen notch length. Suppliers with flexible manufacturing lines can adapt tools and packaging to meet these needs, allowing hospitals and distributors to maintain uniformity across product families.

Biopsy Needle Suppliers run multiple inspections, including dimensional checks, surface evaluations, cutting-edge verification, and stylet-to-cannula alignment tests. These checks reduce the risk of receiving units with dull edges, inconsistent notch sizes, or misaligned hubs.

The design and production comply with ISO8537. The plastic parts are moulded by ...

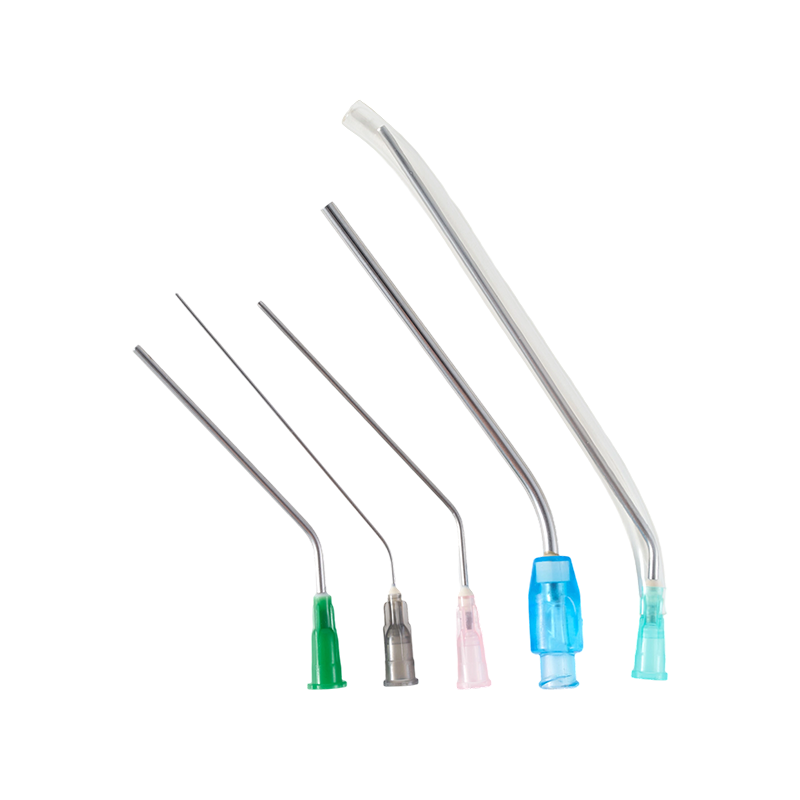

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

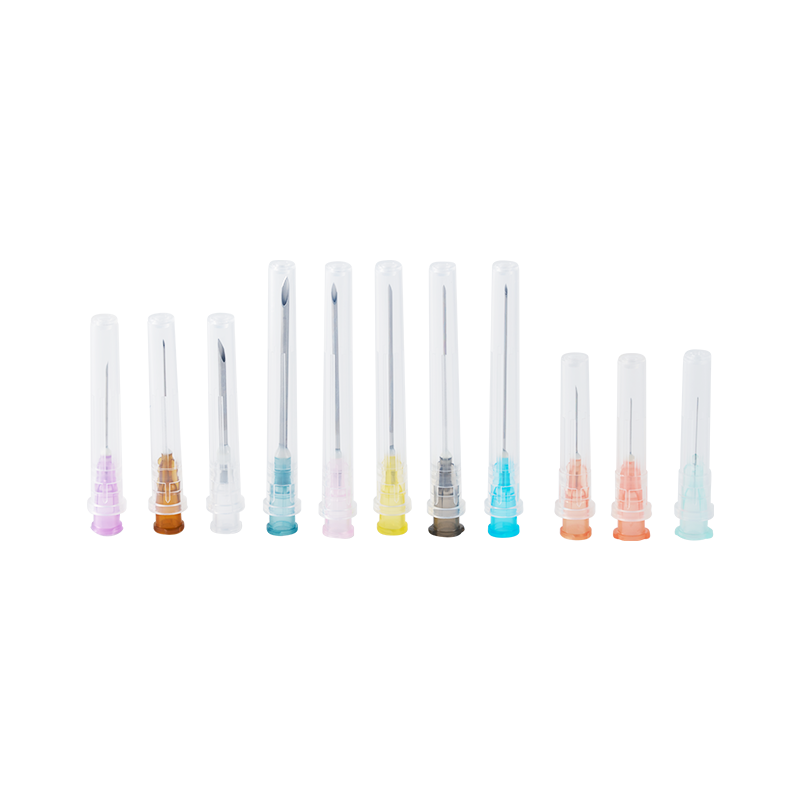

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...