Don't hesitate to send a message

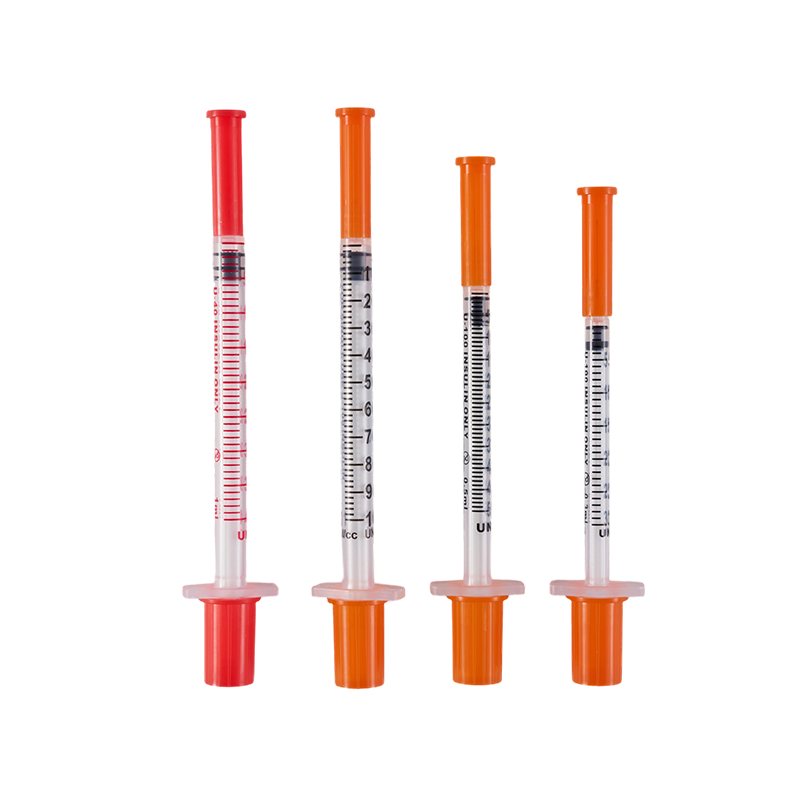

The design and production comply with ISO8537. The plastic parts are moulded by ...

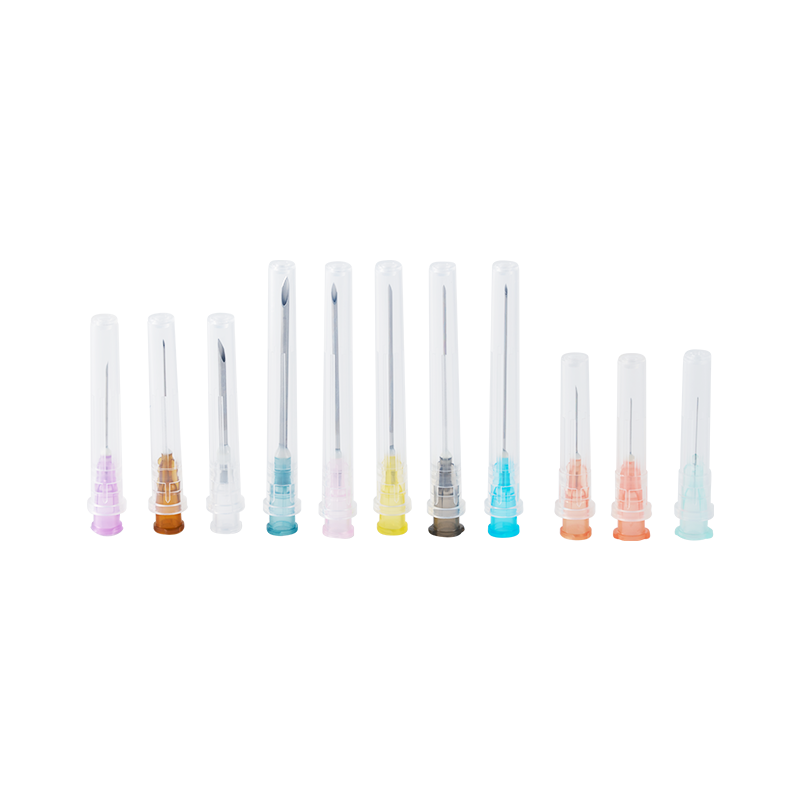

Choosing Hypodermic Needle Suppliers is often about consistency. Many buyers struggle with variability across shipments. A needle may look simple, yet the performance relies heavily on how the cannula is made—its stiffness, polishing, and the accuracy of the grinding angle. Medical-grade SUS304 stainless steel supports the strength and corrosion resistance needed for reliable performance, and the right supplier delivers these qualities in every lot.

A Hypodermic Needle works properly only when the tip geometry is precise. Buyers often ask how sharpness stays consistent, because even small deviations can increase insertion resistance. Our cannula tips are processed on automated grinding systems that set the bevel angle with high accuracy. Long bevel, short bevel, and reverse-grind configurations are available, and each pass is controlled by machines rather than manual processes. The goal is not only to support smooth penetration but also to help clinicians maintain control during use.

A Hypodermic Needle depends on its cannula more than any other component. Material selection, straightness, and internal surface quality all determine how the needle behaves under pressure. After grinding, the cannula passes through electrolytic polishing to remove micro-irregularities. This approach helps create a smooth flow path and minimizes drag during injection or aspiration. Ultrasonic cleaning follows, removing any remaining residues so the cannula is free of contaminants before assembly.

Many hospitals and distributors care about user experience, especially when dealing with high-volume procedures. By refining the sharpness and surface finish, a Hypodermic Needle can support smoother insertion. The combination of SUS304 durability and controlled bevel geometry helps lower puncture force. While patient sensation varies, a high-quality needle helps clinicians carry out procedures with better confidence.

Transportation damage is a common complaint among procurement teams. A cannula tip is easy to distort during long shipments. Suppliers that use foam protection for each group of cannulae help maintain their structural integrity. Outer corrugated or wooden cartons add another layer of protection. This matters for buyers who manage international logistics or multiple warehouse transfers.

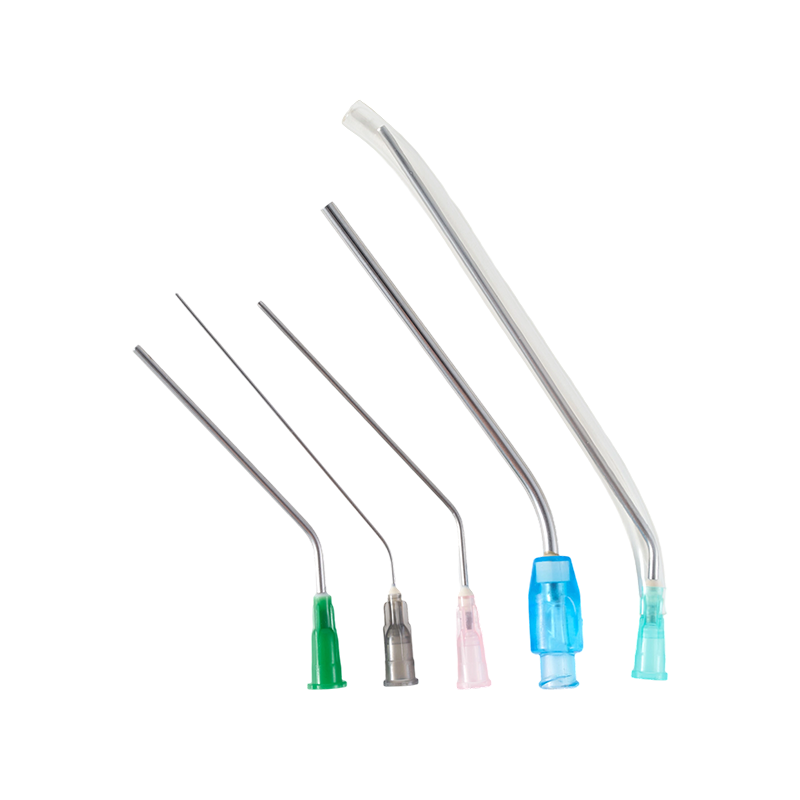

Scalp vein applications require cannulae that balance flexibility with strength. This type of Hypodermic Needle must navigate superficial veins without collapsing. Our cannulae for scalp vein sets go through the same grinding and polishing steps but receive additional inspection for straightness and elasticity. This supports smoother insertion and reduces the risk of kinking during placement.

Asking how a supplier controls each step gives insight into their stability. Another key question is how they manage batch-to-batch measurement. Reliable suppliers keep dimensional data for every production cycle and provide records when needed.

Many clients require gauge-specific cannula dimensions, special bevel types, or reinforced packaging. Hypodermic Needle Suppliers with in-house grinding and polishing equipment can modify specifications without long cycle times. This flexibility helps device integrators build differentiated product lines.

SUS304 stainless steel offers a balance of stiffness and tenacity, giving the needle strength while retaining controlled elasticity. It resists corrosion during sterilization and medication exposure. These characteristics support the lifespan and reliability of the final product.

The design and production comply with ISO8537. The plastic parts are moulded by ...

There are three kinds of the tip types, Sealed-circle with 2 side holes, sealed-...

Assembling with insulin pen, for insulin hypodermic injection.The plastic parts ...

Used in conjunction with an insulin pen, it is used for subcutaneous injection o...

The cannula is made of high quality austenite stainless steel.All the components...

The material of the needle is Medical grade SUS304,which have great stiffness, t...

The barrel is made from high transparent polypropylene(PP),which have a bright a...

The cannula is made of high quality austenite stainless steel.The lancet tip is ...